Whether by road, rail, water or air – the transportation of hazardous goods is an essential task that requires the utmost care. Chemicals, flammable liquids or radioactive substances – all these materials must be safely packaged, labelled and transported in order to minimize risks to people, the environment and infrastructure. But which regulations apply? Who bears the responsibility? And what challenges arise from the constantly updated regulations?

In this comprehensive guide, you will find out what exactly is meant by dangerous goods, which regulations and safety measures must be complied with and how companies can optimize their processes. Immerse yourself in the world of dangerous goods transportation and gain valuable insights into current developments, legal frameworks and proven best practices.

Definition of dangerous goods

Dangerous goods (Hazardous materials) refer to substances or objects that, due to their chemical, physical, or biological properties, can pose a danger to humans, animals, the environment, or property. This danger may arise from various characteristics such as flammability, explosiveness, toxicity, radioactivity, or corrosiveness. In many countries, hazardous materials are subject to specific regulations to ensure their safe transportation, storage, and handling.

There is a clear distinction between the terms dangerous goods and hazardous substances,

although they are often used interchangeably in common parlance:

Dangerous Goods

Dangerous goods refer to substances or products that pose a danger during transport. This includes materials classified as dangerous for transportation under international regulations, such as explosive substances, gases, flammable liquids, corrosive chemicals, and radioactive materials.

Hazardous Substances

Hazardous substances refer to materials that can be potentially dangerous due to their chemical or physical properties but do not necessarily need to be transported in dangerous quantities. These substances pose a risk when released or improperly handled, for example, in the form of vapors or dust.

The distinction is particularly important from a regulatory perspective, as dangerous goods require special regulations for transportation and handling, while hazardous substances are often considered as part of occupational health and safety measures and risk assessments.

Importance of the transportation of dangerous goods

The transportation of dangerous goods plays a crucial role in numerous industries and is of central importance for both the economy and safety. Millions of tons of dangerous goods are transported around the world every year, whether by road, rail, sea or air. Some of the major industries that rely on the transportation of dangerous goods are:

Chemical industry

Highly specialized chemicals and petrochemical products that are potentially hazardous are transported here. This includes liquid, solid and gaseous substances such as petroleum products, chemicals for the pharmaceutical industry and agricultural chemicals.

Pharmaceutical industry

The transportation of medicines, especially liquid or temperature-sensitive preparations that can pose a particular risk, is also of crucial importance. Multimodal transport systems are often used here, which must ensure that the medicines arrive intact and under the right conditions.

Energy supply

The transportation of hazardous materials in the field of energy production and distribution, including oil, gas and radioactivity, is of central importance for securing the energy supply. These goods are subject to strict regulations as they have a high hazard potential.

Aviation and air transportation

The transportation of hazardous materials (e.g. lithium batteries, chemicals or toxic substances) is a particularly challenging issue in the aviation industry. The aviation industry has specific regulations that ensure the safe transportation of these substances.

Waste management

The disposal of hazardous waste, such as chemical waste or contaminated materials, requires safe transportation in order to minimize environmental and health risks.

The frequency of dangerous goods transportation is high in these industries, and it is crucial that both companies and transport companies know and implement the applicable regulations. The creation of safe transport routes, the regular training of the personnel involved and the constant review of safety precautions are essential factors in preventing accidents and minimizing risks.

Legal bases and regulations

The transportation of dangerous goods is governed by a large number of international and national regulations that are intended to ensure the safety of transport routes as well as the protection of people, animals and the environment. The UN Recommendations on the Transport of Dangerous Goods form the basis for many of these regulations, which are implemented in national legislation, such as the Dangerous Goods Transportation Act (GGBefG) in Germany. In addition, there are specific regulations for various modes of transport, such as the ADR for road transport, the RID for rail transport, the IMDG Code for maritime transport and the ICAO-TI and IATA-DGR for air transport.

These regulations differ depending on the means of transportation and the region, but form a highly interconnected system that is applied worldwide. This section explains the most important international regulations and national laws as well as mode-specific regulations.

International regulations

One of the most important international agreements in the field of dangerous goods transportation are the UN Recommendations on the Transport of Dangerous Goods. These recommendations provide a global standard for the safe transportation of dangerous goods and influence national legislation around the world.

UN Recommendations on the Transport of Dangerous Goods: The UN Recommendations form the basis for most international regulations on the transportation of dangerous goods. They were issued by the United Nations and cover both the classification of dangerous goods and specific regulations for their handling, labeling and packaging. The recommendations are integrated as an authoritative reference in various international regulations and contribute to the harmonization of safety standards in the global transport of dangerous goods

National laws

In Germany, the regulations for the transportation of dangerous goods are governed by national laws and ordinances. One of the most important legal bases is the Dangerous Goods Transportation Act (GGBefG), which provides the legal framework for the transportation of dangerous goods by road, rail, waterway and air.

Dangerous Goods Transportation Act (GGBefG): The GGBefG regulates the transportation of dangerous goods on German roads, railways, inland waterways and in the air. It is based on international standards, in particular the UN recommendations, and ensures that national regulations comply with international agreements. The GGBefG defines the rights and obligations of the parties involved, such as the consignor, the carrier and the consignee. It also regulates the requirements for the packaging, labeling and documentation of dangerous goods.

Mode of transport-specific regulations

In addition to the general regulations, there are specific regulations that have different requirements depending on the means of transport. These regulations ensure that dangerous goods are transported safely and efficiently via different modes of transport.

Road transport: Agreement concerning the International Carriage of Dangerous Goods by Road (ADR)

ADR (Agreement concerning the International Carriage of Dangerous Goods by Road): The ADR is the agreement governing the international transport of dangerous goods by road. It sets out detailed requirements for the classification, packaging, marking of packaging units, vehicle marking, safety precautions, and documentation of dangerous goods. The ADR also includes provisions for the training of drivers and the control of dangerous goods transports and information on documentation (e.g., transport documents).

The ADR is regularly updated to respond to new developments and hazards in the area of dangerous goods. It is currently binding for 54 ADR member states, including all member states of the United Nations Economic Commission for Europe (UNECE), as well as voluntary members, and also forms the basis for national regulations in many European countries, including Germany.

Rail transport: Regulation on the International Carriage of Dangerous Goods by Rail (RID)

RID (Règlement concernant le transport international ferroviaire des marchandises dangereuses): The RID regulates the transportation of dangerous goods by rail in Europe. Similar to the ADR, the RID contains specific requirements for the classification, labeling and packaging of dangerous goods transported by rail. It also specifies how the infrastructure for the safe transportation of dangerous goods is to be designed and how emergency situations are to be handled.

The RID is closely linked to the ADR regulations, but is adapted to the special circumstances of rail transport. The RID is regularly revised in accordance with UN recommendations and other international regulations.

Maritime shipping: International Maritime Dangerous Goods Code (IMDG Code)

IMDG Code (International Maritime Dangerous Goods Code): The IMDG Code is the international standard for the transportation of dangerous goods by sea. The code is developed by the International Maritime Organization (IMO) and specifies how dangerous goods are to be classified, packed, labelled and documented on ships. The IMDG Code also includes provisions on cargo securing and safety measures on board ships.

The IMDG Code is one of the most important regulations in international trade and is continuously adapted to take account of new scientific findings and technologies.

Luftverkehr: Technische Anweisungen für den sicheren Transport von gefährlichen Gütern im Luftverkehr (ICAO-TI) und IATA-Gefahrgutvorschriften (IATA-DGR)

ICAO-TI (International Civil Aviation Organization – Technical Instructions for the Safe Transport of Dangerous Goods by Air): These technical instructions from the International Civil Aviation Organization (ICAO) are binding worldwide and regulate the safe transport of dangerous goods by air. They contain regulations on the classification, labeling, packaging and documentation of dangerous goods in air transport.

IATA-DGR (International Air Transport Association – Dangerous Goods Regulations): The IATA-DGR is an international standard developed specifically for the air transportation of dangerous goods. The IATA DGR includes detailed regulations for the safe handling of dangerous goods on passenger and cargo flights. It is particularly important for airlines and freight forwarders and is developed in close cooperation with the ICAO.

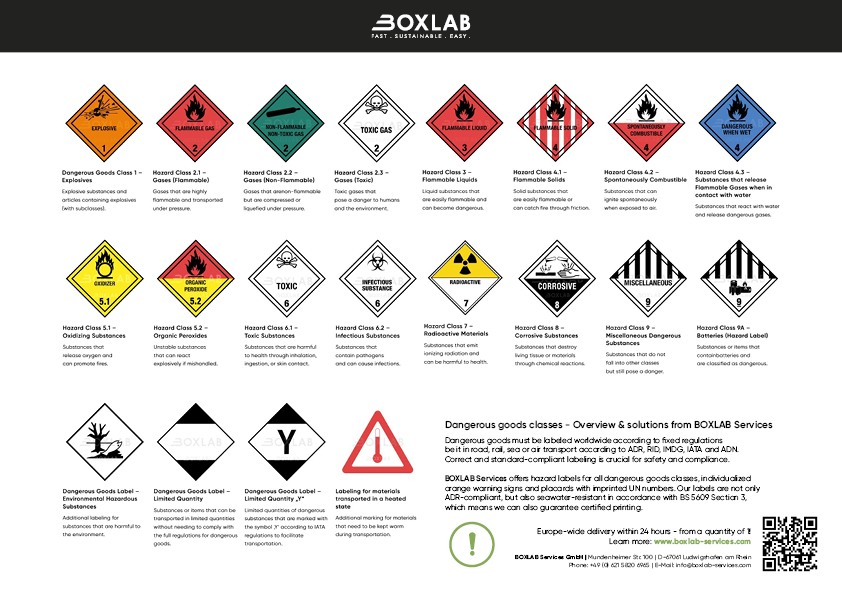

Dangerous goods classes

Dangerous goods are divided into different dangerous goods classes worldwide according to a uniform classification in order to make the handling and transportation of these goods safer. This classification is based on the specific hazards posed by the goods and enables suitable safety measures to be taken. The dangerous goods classes are divided into a total of nine main classes, each of which represents a specific type of hazard. Some classes are further divided into sub-classes, which provide more detailed descriptions of the hazards.

The nine main dangerous goods classes as well as their subclasses and specific markings are explained in more detail below:

Dangerous Goods Class 1 –

Explosives

Explosive substances and articles containing explosives (with subclasses).

Hazard Class 2.1 –

Gases (Flammable)

Gases that are highly

flammable and transported

under pressure.

Hazard Class 2.2 –

Gases (Non-Flammable)

Gases that arenon-flammable

but are compressed or

liquefied under pressure.

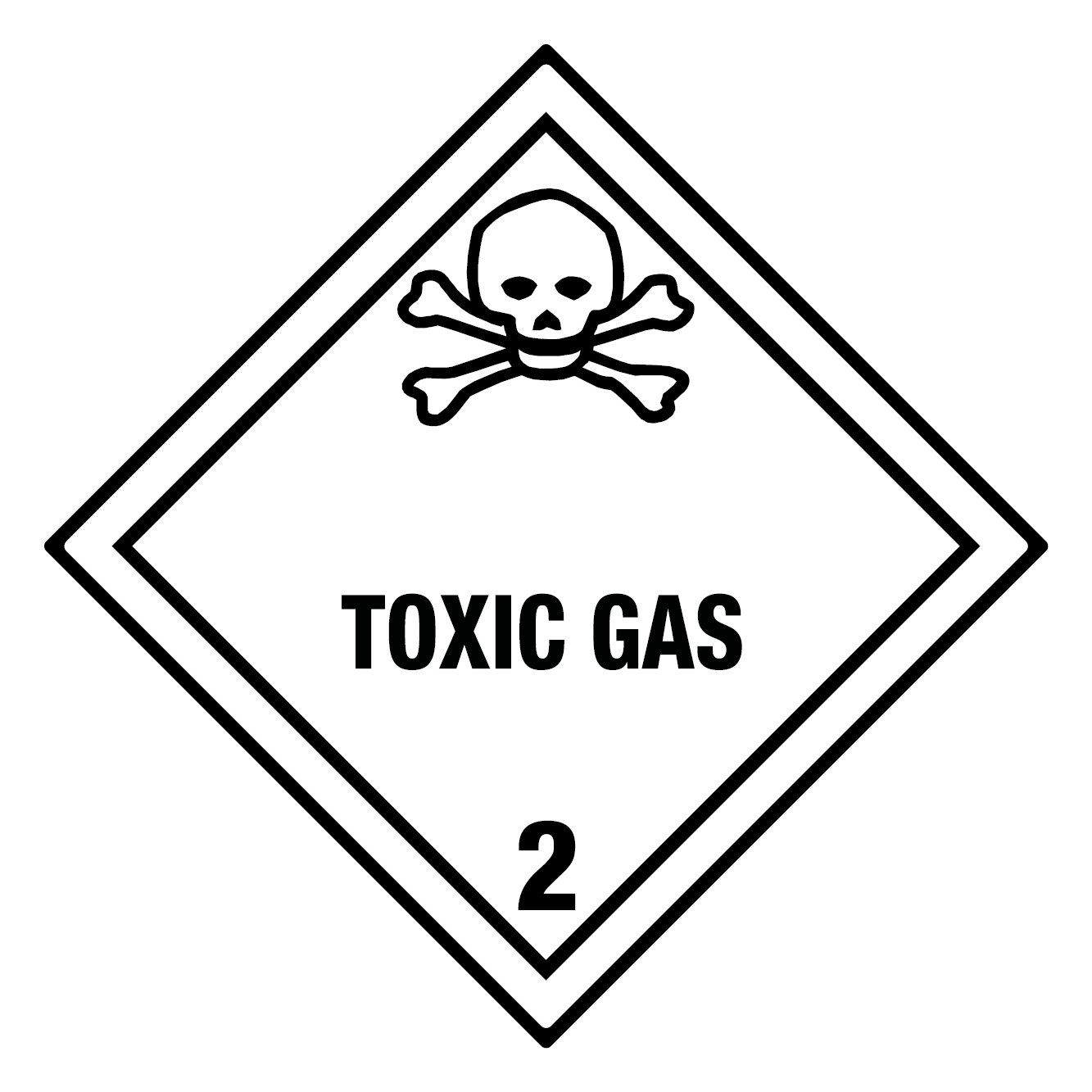

Hazard Class 2.3 –

Gases (Toxic)

Toxic gases that

pose a danger to humans

and the environment.

Hazard Class 3 –

Flammable Liquids

Liquid substances that

are easily flammable and

can become dangerous.

Hazard Class 4.1 –

Flammable Solids

Solid substances that

are easily flammable or

can catch fire through friction.

Hazard Class 4.2 –

Spontaneously Combustible

Substances that can

ignite spontaneously

when exposed to air.

Hazard Class 4.3 –

Substances that release Flammable Gases when in contact with water

Substances that react with water and release dangerous gases.

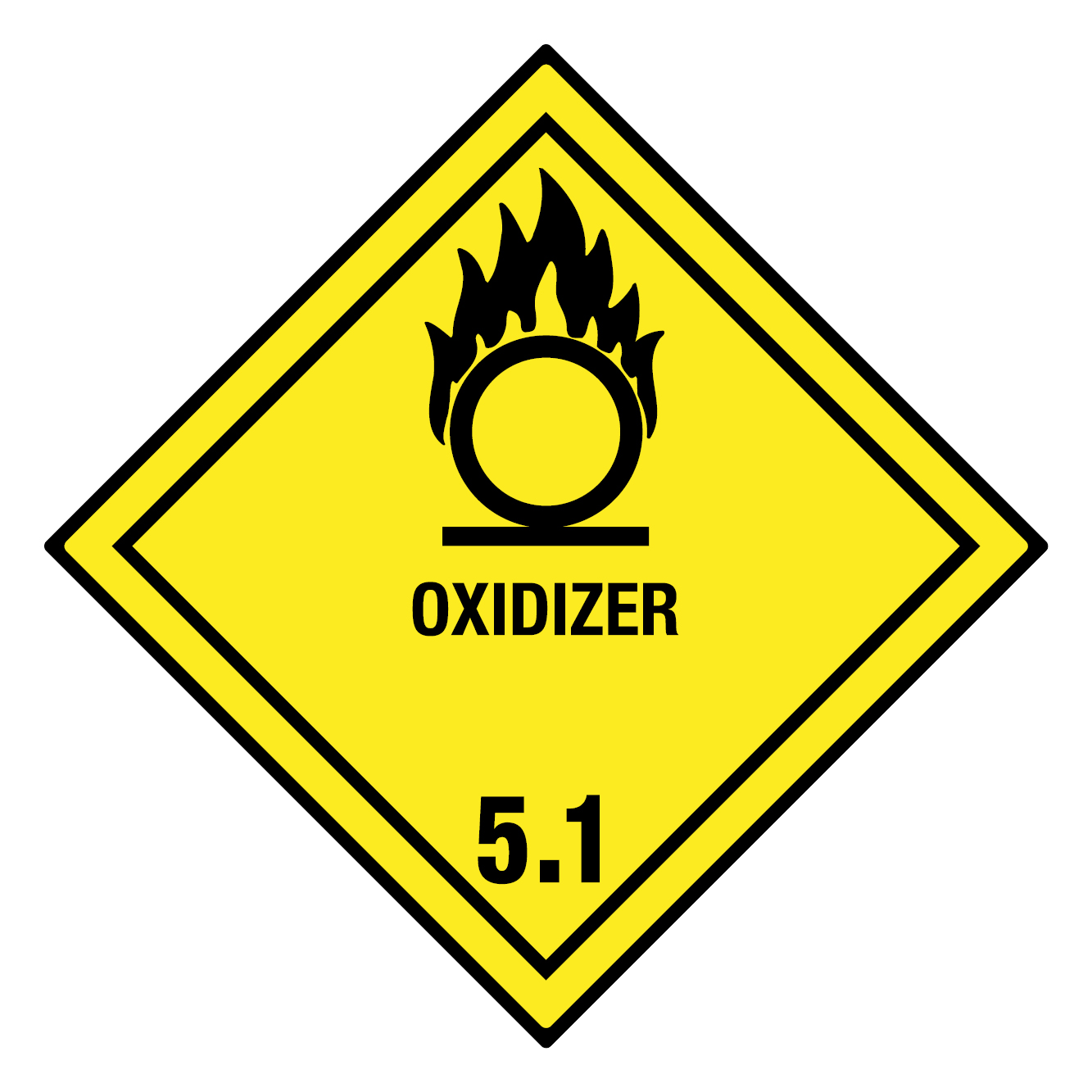

Hazard Class 5.1 –

Oxidizing Substances

Substances that

release oxygen and

can promote fires.

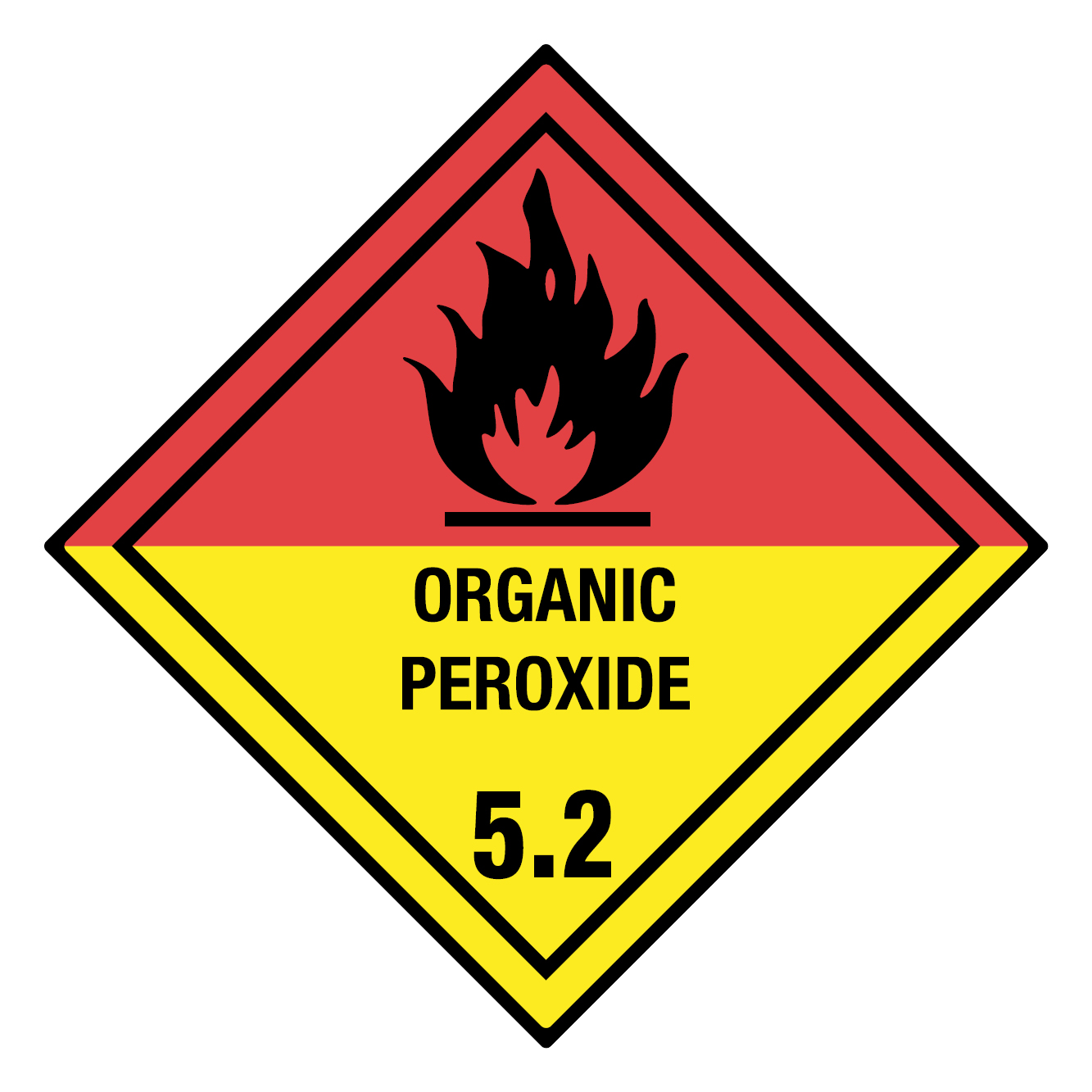

Hazard Class 5.2 –

Organic Peroxides

Unstable substances

that can react

explosively if mishandled.

Hazard Class 6.1 –

Toxic Substances

Substances that are harmful

to health through inhalation,

ingestion, or skin contact.

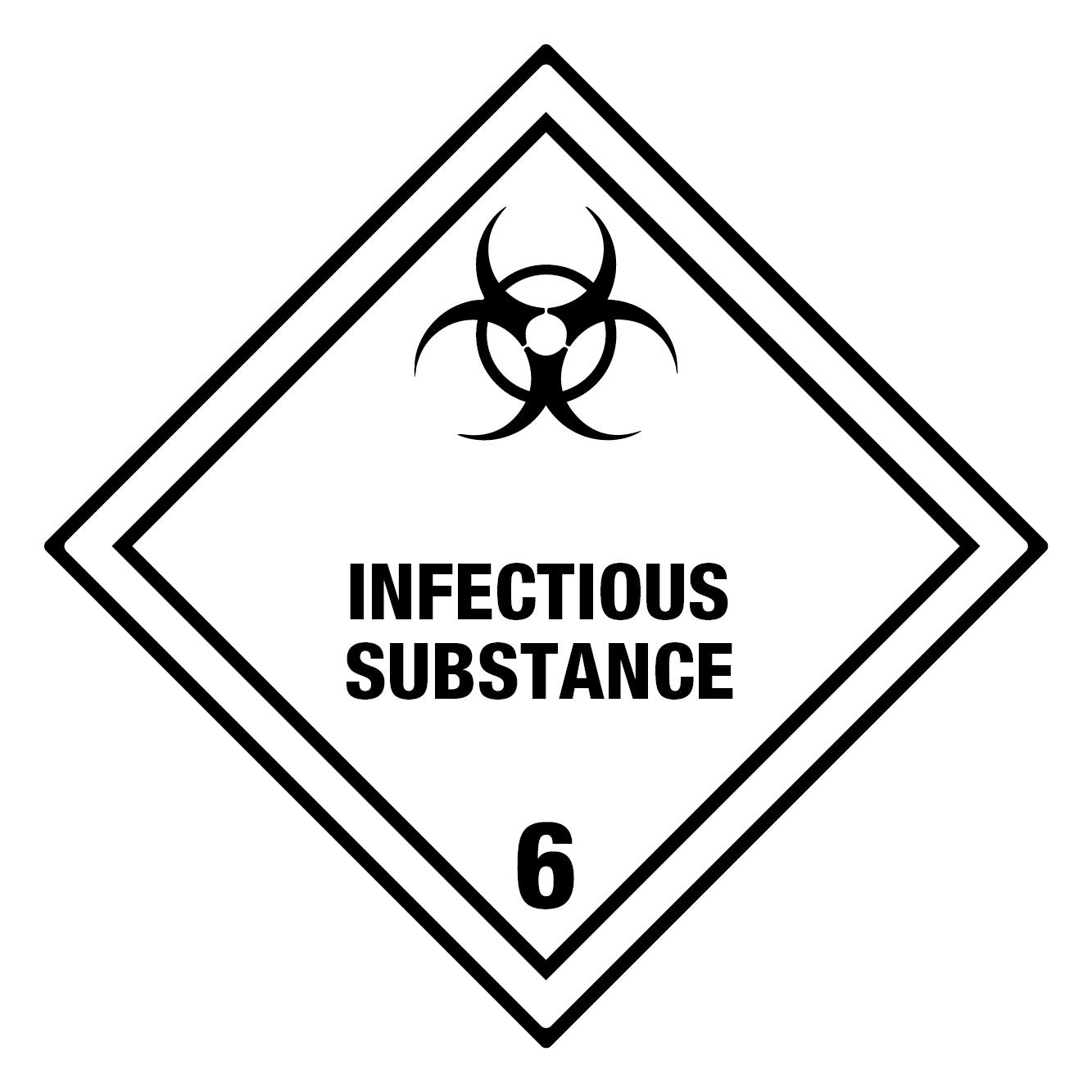

Hazard Class 6.2 –

Infectious Substances

Substances that

contain pathogens

and can cause infections.

Hazard Class 7 – Radioactive Materials

Substances that emit

ionizing radiation and

can be harmful to health.

Hazard Class 8 –

Corrosive Substances

Substances that destroy

living tissue or materials

through chemical reactions.

Hazard Class 9 – Miscellaneous Dangerous Substances

Substances that do not

fall into other classes

but still pose a danger.

Hazard Class 9A –

Batteries (Hazard Label)

Substances or items that

containbatteries and

are classified as dangerous.

Subclasses of class 1

Hazard Class 1.1 – Explosives with mass explosion hazard

Substances that pose a danger to large quantities

of materials and can cause a mass explosion when detonated.

Hazard Class 1.2 – Explosives with explosion hazard when approaching

Substances that are explosive but

do not cause a mass explosion when detonated.

Hazard Class 1.3 – Explosives with fire and explosion hazard

Substances that pose both a fire and explosion hazard

when detonated, but do not cause a mass explosion.

Hazard Class 1.4 – Explosives with low risk

Substances that pose only a low risk

to other materials or people in the event of an explosion.

Hazard Class 1.5 – Very stable explosives

Substances that are very stable

but can still explode if mishandled.

Hazard Class 1.6 – Extremely stable explosives

Substances that are extremely stable and pose no danger

under normal conditions, but are still potentially dangerous.

Subclasses of class 7

Hazard Class 7A – Radioactive Materials (Class A)

This category includes radioactive materials with low activity,

primarily used in medical or industrial applications.

Only hazard labels (100x100mm)

Hazard Class 7B – Radioactive Materials (Class B)

Materials with moderate radioactive radiation,

which must meet strict safety requirements for transport.

Only hazard labels (100x100mm)

Hazard Class 7C – Radioactive Materials (Class C)

Highly radioactive materials that must be transported

under extreme safety measures due to significant radiation hazards.

Only hazard labels (100x100mm)

Hazard Class 7D – Radioactive Materials (Class D)

This category involves special radioactive materials

with specific transport and labeling regulations.

Only placard (250x250mm)

Hazard Class 7E – Radioactive Materials (Class E)

Materials with a very specific classification that

may only be transported under the strictest conditions.

Only hazard labels (100x100mm)

Further markings for hazardous goods

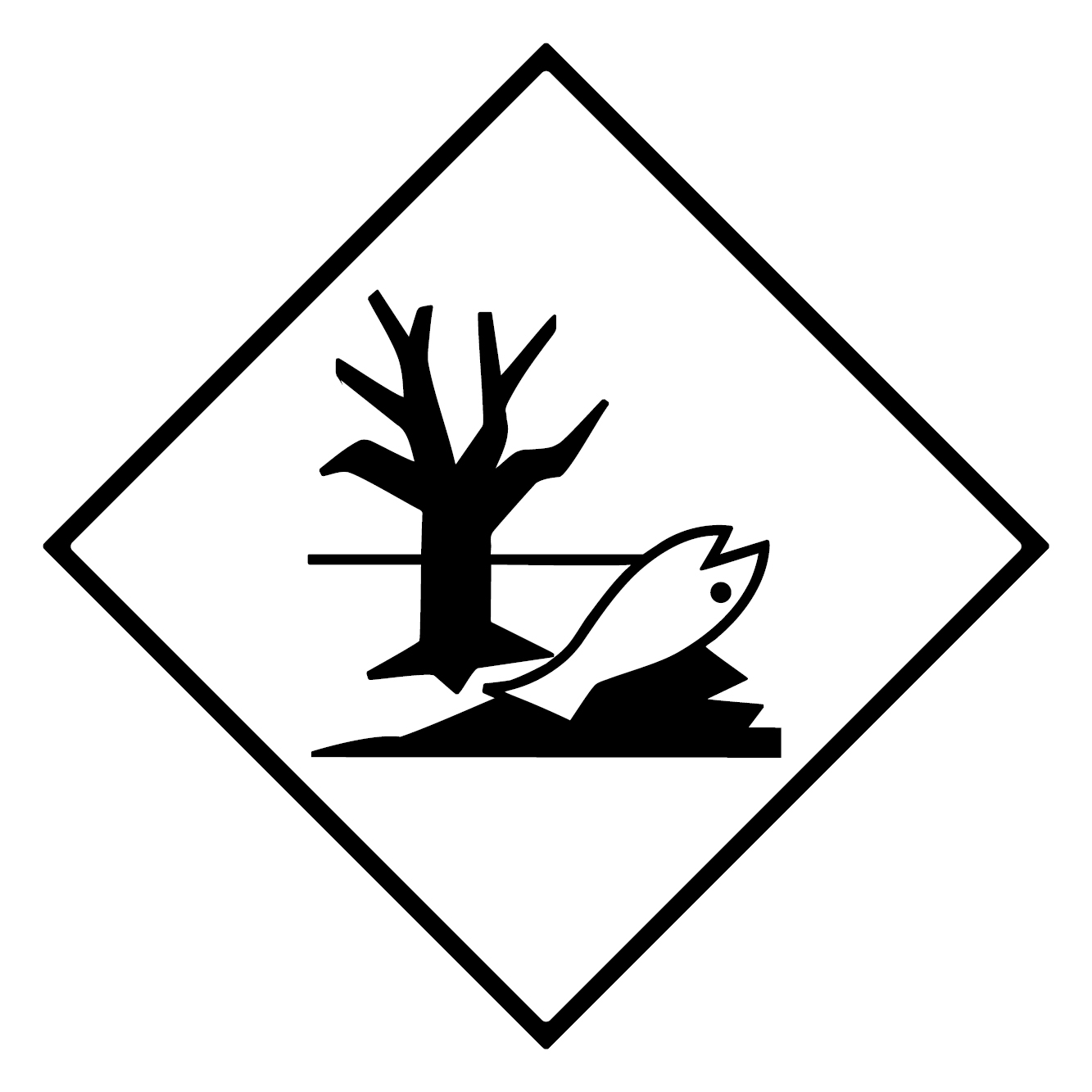

Dangerous Goods Label – Environmental Hazardous Substances

Additional labeling for substances that are harmful to the environment.

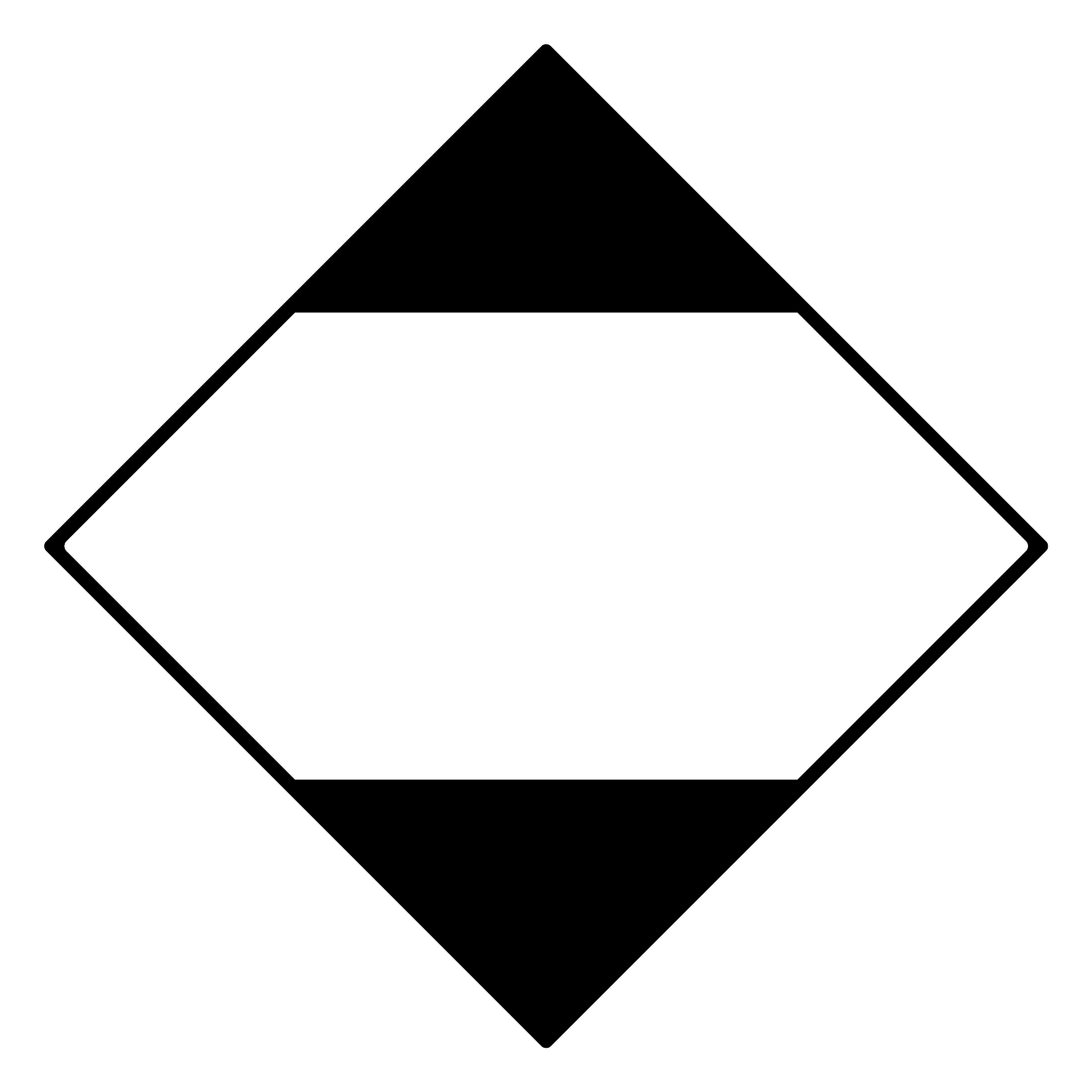

Dangerous Goods Label – Limited Quantity

Substances or items that can be transported in limited quantities without needing to comply with the full regulations for dangerous goods.

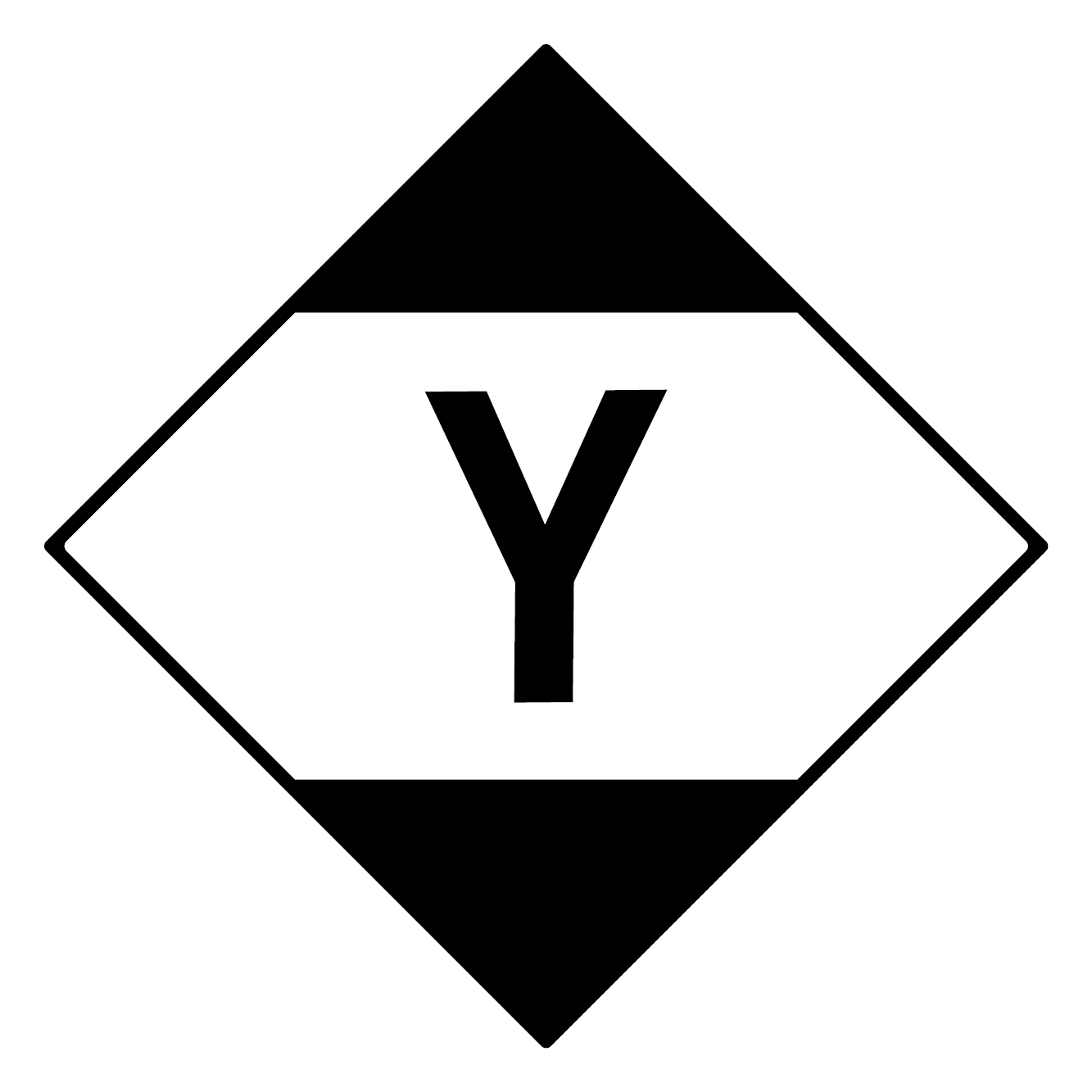

Dangerous Goods Label – Limited Quantity „Y“

Limited quantities of dangerous substances that are marked with the symbol ‚Y‘ according to IATA regulations to facilitate transportation.

Labeling for materials transported in a heated state

Additional marking for materials that need to be kept warm during transportation.

Marking and labeling

Correct marking and labeling are essential for the safe transport of hazardous goods. They ensure that everyone involved can react quickly and correctly in the event of an accident or incident. The hazard signs, warning signs and placards are designed to provide information about the hazardous nature of the transported substances and to facilitate protective measures for all parties involved.

Hazard label

Dangerous goods labels are rectangular stickers that are applied to the packaging of dangerous goods to indicate the type of hazard. They are internationally standardized to ensure uniform labeling of hazardous substances. Dangerous goods labels contain symbols and color codes that provide clear indications of the hazard posed by the contents.

Colors and Symbols

Background color: The colors are highly visible and designed for quick recognition.

Symbol: Each dangerous good has a specific symbol that describes the type of hazard. Examples of symbols include:

- Flame (Symbol for flammable substances)

- Skull and crossbones (Symbol for toxic substances)

- Explosion symbol (for explosive substances)

- Liquid with drops (for corrosive or caustic substances)

Examples of Dangerous Goods Labels

Dangerous goods labels are an essential element of hazardous material labeling and must remain visible and intact throughout the entire transport process.

- Explosive substances (e.g., dynamite)

- Toxic substances (e.g., pesticides)

- Corrosive substances (e.g., acids and alkalis)

- Radioactive substances (e.g., uranium or cobalt-60)

orange warning plates

The orange warning plates are noticeable, orange signs that are attached to transport vehicles carrying dangerous goods. These plates are a crucial feature of road traffic labeling and help emergency services like the fire department, police, and other first responders quickly identify the hazardous nature of the transported goods.

Dimensions of the Orange Warning Plates

The dimensions of an orange warning plate are typically 40 x 30 cm and must be clearly visible on the two long sides of a transport vehicle. These plates are usually made from durable materials to withstand all weather conditions.

Orange Warning Plate Codes

The orange warning plates feature specific hazard numbers (Kemler numbers) that indicate the type and intensity of the danger posed by the transported substance. These numbers consist of two or three digits. The first digit describes the main hazard, while the second and third digits represent additional dangers or a reinforcement of the primary hazard. For example, the number 33 indicates highly flammable liquids, while 90 points to an environmentally hazardous substance. The warning plate is also supplemented by the UN number, which uniquely identifies the transported substance.

Meaning of the Orange Warning Plates

Orange warning plates must remain in place throughout the entire transport, especially on vehicles carrying dangerous goods. The orange plate serves not only to inform drivers but also the police and fire department. In case of an accident, emergency responders can quickly assess the potential hazard of the transport based on the warning plate and take appropriate measures.

Placards

Placards are larger identification signs primarily used on trucks, containers, and cargo vehicles that transport larger quantities of dangerous goods. They are typically 25 cm x 25 cm in size (standard size) and are used under specific transport conditions.

Placards, also known as large labels, are large warning signs affixed to the outside of vehicles such as trucks, containers, or rail tankers to indicate the transportation of dangerous goods. They are designed to allow emergency responders and others to quickly identify the hazardous materials being transported in the event of an accident or incident.

Difference Between Hazard Labels and Placards

- Hazard Labels: These smaller labels are affixed directly to the packaging or shipping items of dangerous goods. They inform about the specific hazard of the respective contents and correspond to the respective dangerous goods classes.

- Placards: These larger signs are attached to the outside of vehicles and identify the type of hazard posed by the loaded goods. They are typically identical to the hazard labels in terms of color, symbolism, and numbering, but are larger to increase visibility.

Placement of Placards

The regulations for affixing placards are internationally regulated, for example, in the European Agreement concerning the International Carriage of Dangerous Goods by Road (ADR). Placards must be affixed to all four sides of a vehicle: front, back, and both sides. For containers or swap bodies, placards are required on all four sides. The standard size of a placard is 250 mm x 250 mm.

Importance of Placards

Placards are essential for safety in dangerous goods transportation. They enable quick and clear identification of the hazardous materials being transported, which is crucial for determining the correct response measures in an emergency. Through their uniform design according to international standards, they ensure that emergency responders and other stakeholders can immediately recognize the specific hazards.

Hazard labels

Welcome to the world of precise labeling with hazard labels from BOXLAB Services. Our products guarantee not only safety, but also compliance with ADR standards. We set standards with first-class durability and crystal-clear legibility. Discover the proven solution from BOXLAB Services today.

Placards

Experience the variety of placards from BOXLAB Services – the indispensable component for the safe identification of dangerous goods. Our placards not only impress with their ADR-compliant design, but also with their exceptional durability and clear presentation. Order now and rely on the proven quality of BOXLAB Services.

Warning signs

Our warning signs provide clear warnings and meet the requirements of international regulations such as ADR, RID, IATA and IMDG Code. With seawater resistance and a practical pull tab, they are the ideal choice for labeling dangerous goods. Order now and optimize the safety of your cargo with BOXLAB Services.

Technical names

Expand your options with our labels with technical names. Developed in accordance with IMDG Code 2023, they provide clear identification for hazardous substances. With seawater resistance in accordance with BS 5609 Section III, they guarantee reliable labeling under extreme conditions. Optimize your dangerous goods labelling with BOXLAB Services.

SPECIAL REGULATIONS, IATA LABELS etc.

Our additional labels include ADR special regulations, IATA labels and general additional labels such as alignment arrows. With our wide selection, we offer flexible options for your individual labeling requirements when transporting dangerous goods. Discover the variety of BOXLAB services for safe and compliant handling of your cargo.

Summary of marking and labeling

Hazard Labels are small stickers placed on dangerous goods packaging that convey specific hazard warnings. They are color-coded and symbolically marked to quickly indicate the type of danger.

Orange Warning Plates are larger orange plates placed on vehicles transporting dangerous goods, containing important dangerous goods codes.

Placards are larger signs used on large transport vehicles like trucks and containers when transporting larger quantities of dangerous goods.

All these labeling elements play a central role in the safe transport and handling of dangerous goods and are an indispensable part of international dangerous goods regulations.

Packaging and securing

The correct packaging and securing of hazardous goods are crucial for safety during transportation. Dangerous goods must be packed, labeled and secured in accordance with the specific regulations in order to avoid hazards to people, the environment and the infrastructure. This section covers the most important aspects of packaging and securing dangerous goods.

Packaging Group I: Highly Dangerous

Substances in Packaging Group I pose a high risk due to their physical properties and the danger they present to life and health. These substances require particularly strong, robust packaging capable of preventing the hazard even in the event of an accident.

Examples: Explosive substances, highly toxic chemicals, highly corrosive substances.

Packaging: For these substances, particularly strong and leak-proof packaging must be used, such as reinforced metal containers or specially treated plastics. The packaging must also withstand additional safety measures such as sealing mechanisms and protective barriers.

Packaging Group II: Moderate Hazard

Substances in Packaging Group II have a moderate hazard potential. They pose a danger but are not as extreme as substances in Group I. However, these substances can still have serious effects if not properly packaged and transported.

Examples: Flammable liquids, toxic gases.

Packaging: For these substances, packaging that is less robust than that for Group I can be used, but it must still meet high safety standards. Frequently, durable plastic containers, metal drums, or barrels are used, ensuring proper sealing and safety measures.

Packaging Group III: Low Hazard

Substances in Packaging Group III present a low hazard. These substances are generally less harmful, but still require appropriate packaging to prevent contamination or dangerous reactions during transport.

Examples: Non-flammable liquids, less hazardous chemicals.

Packaging: For these substances, standard packaging such as plastic containers or barrels made of aluminum or steel can be used, ensuring safe storage and handling without the need for additional safety precautions.

Packaging requirements

The packaging requirements vary considerably depending on the class of dangerous goods, as each substance has different physical and chemical properties. The packaging must always be adapted to the type of hazardous goods and the transportation conditions.

Dangerous goods class 1: Explosives

Packaging: Explosives must be transported in extremely stable packaging that prevents or minimizes the spread of an explosion. The packaging must be certified in accordance with international standards and regularly checked for safety.

Dangerous goods class 2: Gases

Packaging: Gases are packaged in pressurized containers, bottles or cylinders. These containers must be particularly robust and pressure-resistant to prevent leakage or bursting.

Dangerous goods class 3: Flammable liquids

Packaging: Flammable liquids are packaged in tight and robust containers to minimize the risk of leaks and explosions. These containers must be resistant to shocks and temperature fluctuations.

Dangerous goods class 4: Flammable solids

Packaging: For flammable solids, airtight and fire-resistant packaging is used to prevent the substances from igniting.

Dangerous goods class 5: Oxidizing substances and organic peroxides

Packaging: These materials must be transported in special, insulating packaging that protects against external temperature and moisture influences.

Dangerous goods class 6: Toxic and infectious substances

Packaging: These materials must be transported in special, insulating packaging that protects against external temperature and moisture influences.

Dangerous goods class 7: Radioactive substances

Packaging: Radioactive materials must be transported in specially coated and radiation-absorbing packaging that prevents radiation leakage and ensures safe handling.

Dangerous goods class 8: Corrosive substances

Packaging: Corrosive substances must be transported in corrosion-resistant and tightly closed packaging that does not pose a risk to the environment or transportation in the event of a leak.

Dangerous goods class 9: Miscellaneous dangerous substances

Packaging: Different types of packaging are used depending on the type of substance. The packaging must be selected according to the specific hazard properties of the hazardous goods.

Load securing

Proper load securing is necessary to protect hazardous goods from shifting or damage during transportation and to ensure the safety of the entire transport.

Best practices for securing dangerous goods

Safe transportation and load planning

When transporting hazardous goods, a detailed plan must always be drawn up for loading and securing the load. All dangerous goods items should be arranged in such a way that they cannot react with each other and do not pose a hazard.

Use of safety mechanisms

Specific fastening mechanisms such as tension belts, nets and latches must be used to secure the dangerous goods load. These mechanisms must be selected in such a way that they take into account the respective degree of danger of the goods.

Floor and wall anchoring

For larger transports of hazardous goods, specially designed devices should be used to attach the load to the vehicle floor or walls.

Explanation of the provisions

Drivers and transport staff must be trained in the specific regulations on load securing to ensure a high level of safety awareness.

Regular checks during transportation

Regular inspections of the load should be carried out to ensure that no displacement or damage has occurred, especially on long journeys or in dangerous weather conditions.

Proof of load securing:

It is important that a load securing certificate is kept to confirm that the hazardous goods have been secured in accordance with the regulations. This serves both legal protection and transport safety.

Checks by supervisory authorities:

There are regular checks by police and other safety authorities on roads and in ports to ensure that dangerous goods packaging has been carried out correctly and that the load has been properly secured.

Duties and responsibilities

The proper handling of dangerous goods is a complex and risky task that can only be carried out safely and in compliance with the law through close cooperation and clear responsibilities of all parties involved. This section describes the most important duties and responsibilities that must be taken into account when transporting and handling dangerous goods.c

1. Shipper

The shipper (sender) is responsible for the proper packaging, labeling, and documentation of dangerous goods. The main duties of the shipper include:

- Packaging and labeling: The shipper ensures that the dangerous goods are packaged, labeled, and correctly described on the shipping document in accordance with applicable regulations.

- Documentation: They must include the required shipping documents (e.g., dangerous goods manifest, safety data sheet) and ensure that all necessary information for the safe transport of the dangerous goods is available.

- Informing the carrier: The shipper informs the carrier about the type of dangerous goods so that appropriate transport methods and safety precautions can be implemented.

2. Carrier

The carrier (transporter) is responsible for carrying out the transportation and ensuring safety during the transport of dangerous goods. The main duties of the carrier include:

- Safe transportation: The carrier must ensure that the dangerous goods are transported safely and in compliance with all regulations. This includes properly securing the load and using suitable vehicles.

- Document control: The carrier is obligated to check the documents associated with the dangerous goods and ensure that all required paperwork is available.

- Emergency planning: The carrier must ensure that appropriate measures can be taken in the event of an accident or emergency, including providing emergency contact numbers and information.

3. Consignee

The consignee is the party that receives the dangerous goods upon completion of the transport. Their main duties include:

- Inspection of delivery: The consignee must inspect the delivery for damages or irregularities and ensure that the packaging and labeling are correct.

- Compliance with storage regulations: The consignee must store the dangerous goods in accordance with legal requirements, especially if they are hazardous substances that require special storage conditions.

- Reporting problems: If the dangerous goods are damaged or dangerously released during transport, the consignee is required to immediately notify the relevant authorities and the sender.

4. other parties involved

Other parties involved may include logistics companies, loading personnel and regulatory authorities. These parties also play a role in the proper handling of dangerous goods by ensuring safety during loading, unloading and securing transportation.

Training and certification

Handling dangerous goods requires special expertise in order to minimize hazards and comply with legal requirements. It is therefore a legal requirement that all persons who come into contact with dangerous goods must be trained and, in many cases, certified.

Training for staff

- Training requirement: All individuals involved in the packaging, transportation, storage, or disposal of dangerous goods must undergo regular training to ensure they comply with relevant regulations and safety standards.

- Training topics: The training includes topics such as:

- Labeling and packaging of dangerous goods

- Dangerous goods regulations for transport

- Emergency procedures and first aid in case of accidents

- Safety precautions and cargo securing

- Handling dangerous goods documentation

- Training certificate: After successful completion of the training, personnel must receive a certificate or confirmation that proves their successful qualification.

Certifications

In many countries, there are special certification requirements for dangerous goods safety advisors and other specialists who work with dangerous goods. These certificates confirm that the persons concerned have the necessary knowledge and skills to handle dangerous goods safely and in compliance with the law.

Dangerous goods officer

The Dangerous Goods Officer is a central position in the management and organization of dangerous goods transport. According to international and national regulations, such as the ADR (European Agreement concerning the International Carriage of Dangerous Goods by Road), companies that regularly deal with dangerous goods must appoint a Dangerous Goods Officer.

Requirement to Appoint a Dangerous Goods Officer

Obligation: In companies that regularly transport or store dangerous goods, it is mandatory to appoint a Dangerous Goods Officer to monitor compliance with all applicable regulations.

Requirements: The Dangerous Goods Officer must have extensive knowledge of the applicable dangerous goods regulations and transport provisions. They must regularly participate in training to stay up to date with the latest regulations.

Responsibilities of the Dangerous Goods Officer

The Dangerous Goods Officer takes on a variety of tasks that are essential for the safe and legally compliant transport of dangerous goods:

- Monitoring Compliance with Regulations: The Dangerous Goods Officer ensures that all internal processes and transports comply with the relevant regulations.

- Consultation and Support: They advise the company on the correct packaging, labeling, and documentation of dangerous goods and ensure that all safety precautions are in place.

- Training and Awareness: The Dangerous Goods Officer organizes regular training for employees and ensures that all staff working with dangerous goods are informed.

- Emergency Management: In the event of an accident or dangerous goods release, the Dangerous Goods Officer is responsible for coordinating the appropriate emergency measures and informing the relevant authorities.

- Reporting: They maintain records and reports on all dangerous goods activities within the company and ensure that all required documents and certificates are up to date and available.

Special transportation conditions

The transportation of dangerous goods is a challenging task that entails various special requirements and conditions. To ensure that dangerous goods are transported safely and efficiently in all scenarios, specific requirements must be observed. This section covers three key topics in the field of dangerous goods transportation: multimodal transport, temperature-controlled transport and regulations for the transportation of limited quantities and exemptions.

Multimodal transportation

Multimodal transport refers to the transportation of hazardous goods across several modes of transport, such as road, rail, air and water. This can give rise to different requirements and hazards that need to be taken into account in order to ensure safe transportation.

Challenges in multimodal transportation

Coordination of the various modes of transport

Each mode of transport has its own regulations and requirements that must be observed during multimodal transportation. This requires close coordination between the carriers who are each responsible for the relevant section of the transport.

Different regulations

Different modes of transportation (e.g. road and air transport) are subject to different legal regulations and standards. It is therefore necessary to ensure that the correct documents, packaging and safety precautions are in place for each phase of transportation.

Safety aspects

The safety requirements vary depending on the mode of transport and can entail additional complexity and risks when switching from one mode of transport to another, particularly with regard to the securing and labeling of dangerous goods.

Time coordination and delays

Multimodal transportation requires precise scheduling in order to avoid delays and interruptions in transport. Delays can lead to increased risks, especially for hazardous goods, such as sensitive substances.

Solutions for multimodal transportation

Standardization of packaging and labeling:

In order to facilitate multimodal transport, the packaging and labelling of hazardous goods should be standardized and adapted to all relevant regulations. This ensures better comprehensibility and compatibility across different modes of transport.

Documentation and communication:

Clear and complete documentation of the dangerous goods and timely communication between the various parties are crucial. All parties involved must exchange the relevant information quickly and accurately to avoid possible misunderstandings and delays.

Staff training:

All employees involved must be trained on the specific requirements of multimodal transportation. This includes both technical and safety-related aspects in order to comply with the dangerous goods regulations at every stage of the transport.

Temperature-controlled transport

Some hazardous goods require special temperature conditions to ensure their safety, stability and integrity during transportation. Temperature-controlled transportation is particularly important for hazardous substances that either become unstable at high temperatures or can cause dangerous reactions if temperatures are too low.

Requirements for temperature-controlled transportation

Temperature monitoring

Continuous temperature monitoring is essential. For the transportation of temperature-sensitive dangerous goods, special thermal monitoring devices must be used to ensure that the temperature remains within the safe range throughout the transport.

Packaging

The packaging must be designed in such a way that it can maintain a constant temperature, e.g. by using insulating materials or temperature-regulating containers. In some cases, cooling or heating elements may also be required to ensure the prescribed temperature.

Means of transportation

Temperature-controlled transport requires specialized vehicles, such as refrigerated trucks, containers or aircraft, which are able to maintain the necessary temperature over longer documentation and control: distances.

Documentation and control

As with other types of transportation, the temperature regime during transport must be fully documented. This includes temperature logs, which can be used as proof of compliance if required.

Special requirements for specific types of dangerous goods

Pharmaceutical products and chemicals:

Certain pharmaceuticals or chemicals require a constantly cooled environment to guarantee their effectiveness and safety. In these cases, special regulations regarding the temperature range must be observed.

Food and food additives:

The transportation of hazardous foods or additives, which are considered dangerous goods, also requires temperature-controlled transport to prevent contamination or spoilage of the goods.

Limited quantities and exemptions

There are special facilitations for the transportation of limited dangerous quantities. These regulations primarily concern small quantities of hazardous goods that are not considered dangerous in a transport volume or that have less serious consequences. This reduces the administrative burden for companies.

Regulations for limited quantities

Definition of limited quantity:

A limited quantity is a defined upper limit up to which dangerous goods are not considered dangerous in terms of transportation. These quantities are defined in international regulations (e.g. ADR, IATA) and vary depending on the type of dangerous goods.

Labeling and documentation:

Although these quantities are considered less hazardous, certain regulations regarding labeling and documentation must also be observed here. For example, limited quantities must be clearly labeled and the transport must be correctly documented.

Packaging:

Simplified packaging requirements often apply to limited quantities. In many cases, less complex packaging is sufficient to transport the hazardous goods safely.

Exemptions and facilitations

Simplifications for labeling:

Some hazardous goods that are transported in limited quantities are not subject to the full regulations for labeling and documentation. For example, there is no need for certain hazard labels or additional transport documents.

Easing the load securing requirements

In some cases, the requirements for load securing are less strict, as the risk is considered to be lower for limited quantities.

Simplified transport regulations:

As part of the exemptions, the regulations for the transport route, the means of transport or the necessary permits can be simplified, which leads to a reduction in logistics costs.

Current developments and trends

The field of hazardous goods transportation is subject to constant change. New regulations, technological innovations and a growing awareness of sustainability influence the industry and offer both opportunities and challenges for companies that handle hazardous substances. This section highlights the most important current developments and trends in the field of hazardous goods transportation.

Technological innovations

The integration of new technologies into the transportation of dangerous goods is a key factor in increasing both safety and efficiency. Technology is playing an increasingly important role in dangerous goods logistics, both to minimize risk and to optimize operations.

Important technological developments

Digital monitoring systems

The use of Internet of Things (IoT) technologies to monitor dangerous goods during transportation is on the rise. Intelligent sensors can monitor information such as temperature, humidity, vibrations and other environmental conditions in real time. These systems help to detect problems at an early stage and take immediate action if necessary.

Drones and autonomous vehicles

The use of drones for monitoring the transportation of dangerous goods and inspecting storage sites or transport routes is a growing trend. These technologies offer the possibility of reacting more quickly to hazards and improving the safety of transportation. Autonomous vehicles are also being developed for the transportation of hazardous goods, which could potentially increase the efficiency and safety of transport.

Use of blockchain for tracking dangerous goods

Blockchain offers a unique opportunity to ensure the traceability of dangerous goods transportation and transactions. With this technology, all relevant information about the transport process can be stored decentrally and transparently, thus avoiding forgeries and errors in documentation.

Automated hazardous goods labeling

Some companies are using artificial intelligence (AI) and machine learning to automate the dangerous goods labeling process. This enables faster and more accurate labelling of dangerous goods and minimizes human error.

Sustainability

Sustainability is a growing issue in the transportation of dangerous goods. There is increasing pressure from governments, society and companies themselves to reduce the environmental impact of transportation. While the transportation of dangerous goods poses particular risks, there are also increasing efforts to reconcile these risks with more environmentally friendly and sustainable solutions.

Measures to reduce the environmental impact

Energy efficiency in transportation

The trend is moving towards more energy-efficient means of transportation, in particular the use of electric vehicles and alternative fuels (such as hydrogen), in order to reduce CO2 emissions in the transportation of hazardous goods. Rail transport is also seen as an environmentally friendly option that emits less CO2 than road transport.

Packaging innovation

More sustainable packaging for hazardous goods is another important trend. Companies are increasingly turning to recyclable and biodegradable materials to reduce waste and minimize environmental impact. Reusable packaging is also being developed to reduce the need for disposable packaging.

Optimization of logistics

By using intelligent route planning and logistics systems, companies can increase the efficiency of their hazardous goods transportation and avoid unnecessary empty runs. This not only reduces costs, but also CO2 emissions and fuel consumption.

Carbon compensation

Some companies in the hazardous goods transportation sector invest in carbon compensation projects to offset their emissions. These include investments in reforestation projects or the use of renewable energies in production.

Effective accessories for your success

Our range includes thoughtful solutions designed to increase your efficiency and streamline workflows.

Our PE boards offer a durable and residue-free surface for safe labeling. The BOXLAB cleaning cloth, when used with the BOXLAB BIO Cleaner, ensures thorough cleaning to guarantee optimal label adhesion. For professional applications, we also offer spray adhesive that ensures reliable attachment.

Our training materials support trainers and professionals with practical solutions, including training sets with hazard labels and magnetic placards.

PE Boards

Our PE boards are high-quality products that serve as the ideal surface for labels. Thanks to their robust properties and the ability to label without additional cleaning effort, they provide an efficient solution for various applications. The PE boards are lightweight, easy to handle, and suitable for both indoor and outdoor use. With their durable construction, they are a reliable support in your labeling process.

Auxiliaries

Our aids are not just simple tools, but indispensable companions for your labeling processes. From injury-free safety scrapers to environmentally friendly BIO cleaners and the practical BOXLAB squeegee – each of our tools has been developed to make your day-to-day work easier and ensure legally compliant results. Quality and functionality are at the heart of our products.

Training sets

Our training sets offer a practical introduction to the world of dangerous goods labeling and packaging. They contain high-quality samples of dangerous goods labels as well as complementary accessories such as safety scrapers and BIO cleaners. These kits are ideal for training and education to provide professionals with a comprehensive overview of legal requirements and best practice.

Spray adhesive

Our spray adhesive is the ideal solution for demanding conditions. Whether in rain, snow or difficult surfaces – it ensures reliable adhesion of your labels. Even labels that have already been removed can be easily reattached without compromising security. Developed for professional use, our spray adhesive provides a strong and durable bond. Discover the optimum support for your labeling – even under the toughest conditions!

BOXLAB machine cleaning cloth

With a high-quality cotton-polyester blend, ideal for machine cleaning, surface care, and container cleaning – perfectly combined with the BOXLAB BIO Cleaner for optimal results. The BOXLAB Machine Cleaning Cloth (400x400mm), made from a durable cotton-polyester blend, offers exceptional durability and absorbency for demanding cleaning tasks. Its generous 40 x 40 cm size makes it perfect for machine, surface, and container cleaning. The double overlock stitching prevents fraying and guarantees long-lasting durability. Combined with the BOXLAB BIO Cleaner, it ensures thorough and effective cleaning that supports the adhesion of hazardous material labels. Ideal for professional use – in auto repair shops, logistics, and for label preparation.

Das Bild zeigt den BOXLAB BIO-Reiniger zusammen mit einem BOXLAB Maschinenputztuch im Motorraum eines Fahrzeugs. Das Tuch liegt auf einer verschmutzten Oberfläche und verdeutlicht die effektive Reinigung von öligen und schmutzigen Bereichen. Durch die Kombination aus hochwertigem Maschinenputztuch und dem BOXLAB BIO-Reiniger lassen sich Motorraum und andere schwierige Oberflächen schnell und gründlich säubern, um eine ideale Grundlage für Etikettierungen oder weitere Reinigungsprozesse zu schaffen.

Safety and regulations at a glance

The transportation of dangerous goods is an essential part of many industries, but requires a high level of safety and legal compliance. From classification into different dangerous goods classes and correct labelling to packaging, securing and responsibilities – every aspect is clearly regulated to minimize risks.

Whether by road (ADR), rail (RID), sea (IMDG Code) or air (IATA-DGR) – compliance with the relevant regulations is crucial for safe and legally compliant transportation. Current developments, technological innovations and sustainable solutions are also playing an increasingly important role.

For companies that transport or handle dangerous goods, it is essential to keep up to date with new regulations and best practices. BOXLAB Services supports you with high-quality dangerous goods labels, sustainable solutions and practical products for the safe and efficient handling of dangerous goods.

We are always there for you personally.

Contact us now and find out more

about BOXLAB Services.

We look forward to your inquiry or a brief conversation. Or use our contact form. Our team will be happy to answer your inquiry and get back to you as soon as possible.