Date:

August 22, 2022

Categories:

Placards, Products, Tips & Tricks,

Placards are not just labels. Placards must comply with international guidelines to ensure that the entire transport of dangerous goods is legally compliant. However, it is not just the placard itself that is important. Although certified placards are a prerequisite for legally compliant transport, it is also important to label in a legally compliant manner. Therefore, the following mistakes must be avoided at all costs so that the placard is also attached firmly, clearly visible and in the right place over the entire transport route.

1. STORAGE

Temperature

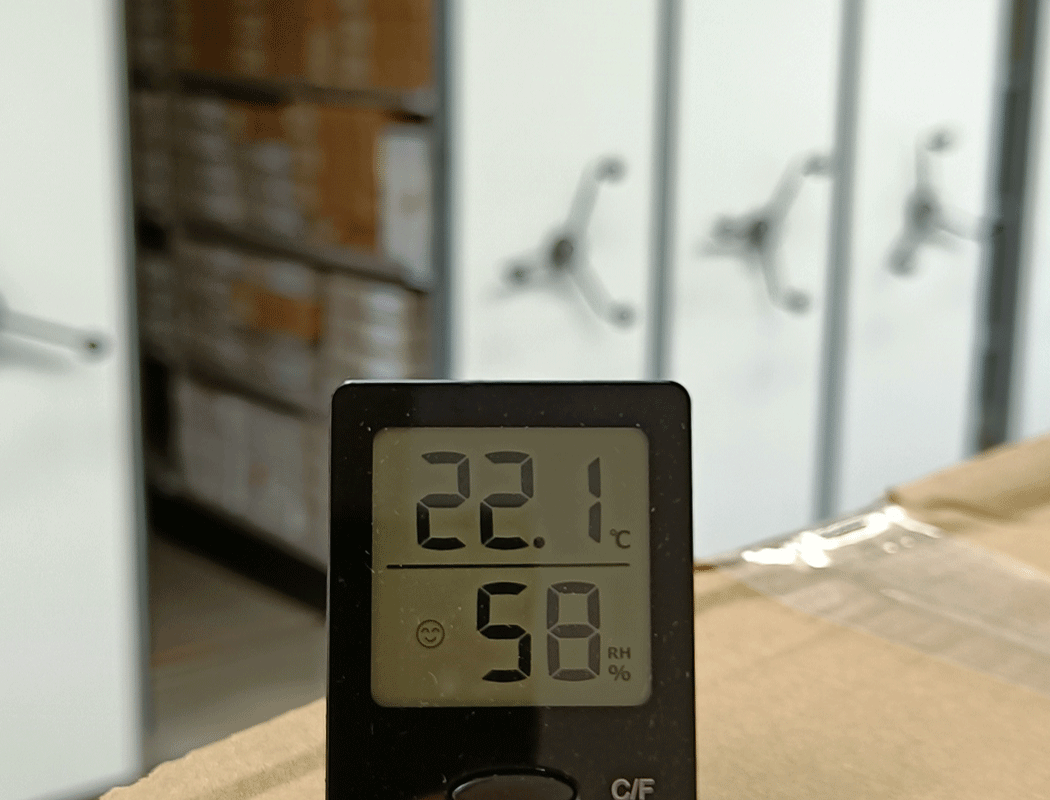

Contrary to prevailing opinion, placards are highly complex products. The composition of adhesive and film material, when ideally stored, provides the conditions for meeting the legal requirements regarding adhesion and seawater resistance. These are certified after appropriate tests. To ensure that this certificate remains valid for the customer, the placards must be stored in accordance with the manufacturer’s instructions. At BOXLAB Services, this means a temperature range of 15-25°C and a humidity of approx. 50%.

Packaging

Despite temperature-controlled storage, it is still possible that the placard / placard size may detach from the backing paper or curl during prolonged storage. Depending on the material, the films can also become statically charged. BOXLAB Services stores its placards in practical, stable cardboard boxes of 250 pieces each. These can be stacked several times without passing on the pressure to the placards inside. They also protect against light incidence and small temperature fluctuations during transport and storage.

Duration

Similar to temperature and humidity, a blind eye is often turned to the shelf life of hazardous goods labels. However, here, too, the certificate for seawater resistance expires after the best-before date. The adhesive, for example, dries out after a while even in ideal storage. Depending on the material, this becomes brittle and fragile. The ink anchoring also increasingly loses its effectiveness. All placards that BOXLAB Services delivers to you have a shelf life of one year.

2. UNDERGROUND

Wet/cold

Placards‘ adhesive has been developed to develop its full adhesive power on surfaces that are as clean, flat and dry as possible. Wetness and cold are therefore frequent sources of errors when labeling – especially in winter. It is therefore advisable to find as dry a place as possible for labeling and to dry the surface as well as possible.

Dirt

An unfortunately common practice is to put the label on the container as it stands in front of you. However, it is not uncommon for the containers to be slightly to heavily soiled – after all, most containers come directly from the street. In the worst case, this can lead to the placard having a certain initial adhesion, but this ultimately only exists between the dirt and the placard. Rain, for example, then washes the dirt, including the placard, off the container.

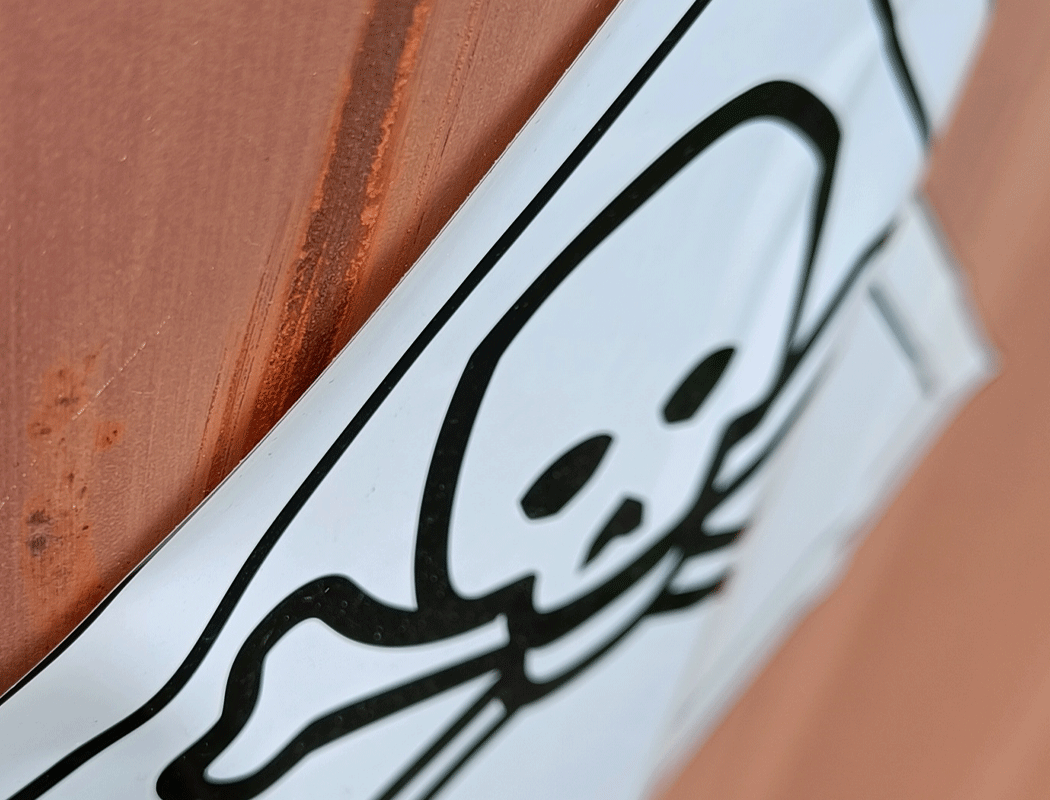

Damage/rust

Quite similar to dirt is the situation when the placard is applied to a damaged surface. For example, if possible, labeling on rust should be avoided. Since both rust and placard „work“ with temperature fluctuations, there is a high probability that the placard will slowly detach at this point, making it more susceptible to rain, dirt or strong driving winds. The same applies, for example, to dents and areas with peeling paint or sticking to old adhesive residues.

3. LABELING

Adhesive damaged

Similarly to incorrect storage, the adhesive also loses some of its effectiveness if it is subjected to too much stress before labeling or if it is removed from the film material; this can happen, for example, through frequent or extensive touching of the adhesive surface with the hand or gloves.

Contact pressure

The same problem exists here as with rust – the only difference being that damage to the placard can occur as soon as the label is applied. A lack of contact pressure when applying the placard increases the probability that the placard will detach from the container within the first 24 hours. This is because the adhesive needs this time to develop its full adhesion. Using a squeegee can improve the initial adhesion by 50%, giving the label a better chance to develop its full adhesive power. This does not mean that every container should not be moved for 12 or 24 hours after labeling – but the initial period is crucial to ensure that the placard remains in place throughout the entire transport process.

Air bubbles

Even though it’s a nagging issue with stickers and labels: air bubbles not only look unsightly, they also have a direct impact on the label’s adhesion. Here, too, the air works underneath the film and slowly shifts. As a result, the loose area becomes larger and larger and can loosen the placard all the way to the edge. Therefore, it is better to poke the bubble with the smallest possible hole and press again. The use of a squeegee helps to label as bubble-free as possible.

AVOID ERRORS WITH BOXLAB SERVICES

BOXLAB Services supports you not only as a supplier but also as a process optimizer. In addition to the corresponding placards, we offer various tools to help you optimize the entire process and achieve consistent results.

Services

BOXLAB Services also supplies individualized placards in quantities as low as 1, Europe-wide in 24 hours. This eliminates unnecessary minimum quantities in the four- or five-digit range. This creates flexibility and simplifies warehousing for our customers.

Quality

All dangerous goods labels are seawater resistant according to BS5609 Section 3 and comply with IMDG Code, RID, ADR, IATA. This also applies to individualized labels, such as warning plates or placards with imprinted UN number. In addition, our placards have a separate peel-off edge for better handling at the loading point.

Your personal contact

Are you interested in a product presentation or a sample?

We will be happy to help you.