Date:

January 20, 2025

Categories:

Company, Industry News, Products, Sustainibility, Tips & Tricks,

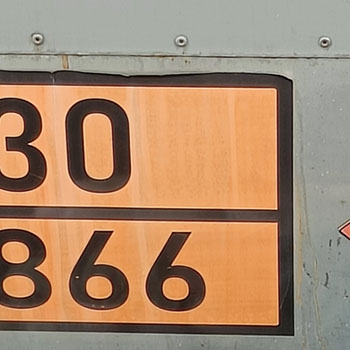

The safe labeling of hazardous goods transports and storage areas is an essential safety measure in logistics. Incorrect or improper labeling of hazardous substances can have serious consequences for people and the environment. BOXLAB PE signs offer a legally compliant, sustainable and efficient solution for hazardous goods labeling in road, rail and sea transport.

Our PE plates made of high-quality polyethylene (PE) are specially developed for demanding conditions and enable the safe, residue-free application of hazardous goods labels. Thanks to their weather resistance, chemical resistance and durability, they offer a superior alternative to conventional solutions such as metal plates or direct labeling.

Why BOXLAB PE boards?

1. Residue-free label removal

Thanks to special material properties, BOXLAB labels can be removed effortlessly and without leaving any adhesive residue. This allows for quick and efficient relabeling without additional cleaning effort.

2. Maximum longevity and resistance

Our boards are UV-resistant, chemical-resistant and temperature-stable, which means they can be used reliably even under extreme conditions.

3. Lightweight and easy to handle

Compared to metal panels, PE panels are significantly lighter and make assembly and transport much easier.

4. Sustainability through 100% recyclability

Our PE boards are fully recyclable, making them an eco-friendly choice for sustainable businesses.

5. Protection for your transport containers

BOXLAB PE panels prevent damage to containers and vehicles and thus contribute to the longevity of your means of transport.

6. Certified security

BOXLAB PE panels are seawater certified to BS 5609 Section III, ensuring long-term label adhesion in even the most extreme conditions.

7. Process optimization

The standardized size and easy handling significantly reduce labeling time and costs.

Technical product details

Material: Polyethylene (PE), robust and durable

Sizes: 290 x 290 mm | 401x301mm

Thickness: 3.0 mm

Weight: Lightweight for easy handling

Color: Black (default)

Certification: Seawater resistant according to BS 5609 Section III

Wide range of applications

Dangerous goods transport:

Ideal for tank containers, sea containers, tank cars and trucks.

Warehouse identification:

Perfect for shelves, storage areas and hazardous materials warehouses.

Construction sites:

Robust signage for temporary safety and hazard warnings.

Industry & Production:

Can be used flexibly for marking machine and production areas.

Comparison

| Criteria | BOXLAB PE-Board | Metal Plates | Direct Labeling |

|---|---|---|---|

| Corrosion Resistance | No rust, weather-resistant | Rusts in moisture | Not relevant |

| Weight | Light and easy to handle | Heavy and difficult to handle | Light |

| Cleaning | No cleaning effort required | High maintenance effort | Requires removal of adhesive residues |

| Sustainability | 100% recyclable | Limited recyclability | Frequent replacement needed |

| Theft Protection | No scrap value, low risk | High scrap value | No theft risk |

| Process Costs | Low due to easy handling | High due to maintenance | High due to re-labeling |

Assembly & handling

Insert PE panel into holder or mount directly.

Apply the BOXLAB label bubble-free using a squeegee.

If necessary, remove the label without leaving any residue and re-label.

FAQ

Are BOXLAB PE sheets reusable?

Yes, they can be used several times and provide a sustainable labeling solution.

Can the panels be used in extreme weather conditions?

Yes, the boards are UV-resistant, chemical-resistant and seawater-certified.

Which labels can be used on the PE sheets?

BOXLAB labels are specially developed for use with PE sheets and therefore deliver the best results.

Are there different sizes and mounting options?

Yes, BOXLAB PE boards are available in different sizes and can be mounted flexibly.

How is the order and delivery handled?

Orders can be placed via our online store. We offer fast and reliable delivery options.

Labeling errors: an often underestimated risk

Many retailers underestimate the importance of correct labeling. Common problems arise from:

- Missing labeling: This is a clear violation of legal regulations.

- Incorrect label formats or layouts: Labels that do not meet applicable standards (e.g. incorrect size, inappropriate colors or symbols) may also be subject to complaint. Incorrect labeling is legally assessed in the same way as completely missing labeling.

- Illegible or damaged labels: These can also be considered inadmissible and mean that the dangerous goods may not be transported.

Consequences of violations

- Fines: These apply not only for missing labeling, but also for incorrect labeling.

- Legal liability: Incorrect labeling can lead to accidents for which the dealer will be held liable.

- Loss of image: Such mistakes can permanently damage customer trust.

Get free advice now

Contact us today to find out more about our dangerous goods labels and other intralogistics solutions and to arrange a personal appointment.