Current challenges in labeling:

UNIQUE METHODS:

There are currently no standardized methods for attaching hazardous goods labels. Common methods include self-adhesive labels, paper-based labels with glue or fixing with spray adhesive.

REMOVAL AND RETENTION:

Old labels need to be removed after transport closures, which is often problematic. Common methods such as chemical cleaners, razor blades or glass scrapers pose a risk to employees and can permanently damage the container surfaces.

PROBLEMS DURING RE-application:

Damaged or dirty surfaces prevent even label adhesion. Adhesive residue and uneven surfaces lead to bubble formation, which means that the new labels do not adhere permanently and may even be lost.

USE OF METAL PLATES:

Metal plates as label carriers are a common alternative. However, these merely shift the problem to the plate itself. They are heavy, expensive, prone to rust and a frequent target for theft due to their scrap value. They also require regular, time-consuming cleaning.

ENVIRONMENTAL AND SAFETY ASPECTS:

The use of aggressive cleaning agents, spray adhesives that are hazardous to health and sharp tools

and sharp tools not only causes high environmental pollution, but also increases the risk of

also increases the risk of injury for employees. The lack of reusable options and inadequate

recycling concepts further exacerbate the problem.

Solution approaches

Future-oriented solutions should be based on modern material technologies that can withstand extreme weather conditions, mechanical stress and chemical influences. Only through a combination of new materials, clever design and well thought-out recycling concepts can hazardous goods labeling be made sustainable, safe and economical. This vision should guide developments in the logistics sector.

Innovation through a certified complete solution

Our PE panels in combination with BOXLAB labels offer a globally unique, seawater-certified overall solution in accordance with BS 5609 Section III. While many manufacturers only have their labels certified, our solution offers complete safety for labeling thanks to optimally coordinated components – even under extreme conditions such as at sea, on the railroads or in road traffic. You can also order pre-labeled plates from us. As sheets and labels are made from the same material, both can be recycled together – this simplifies disposal, optimizes processes and promotes sustainability.

Material properties of PE panels

Our PE boards are made of robust, recyclable polyethylene and offer numerous advantages over traditional solutions:

RESIDUE-FREE LABEL REMOVAL:

Thanks to special material properties, BOXLAB labels can be removed effortlessly and without adhesive residue

DURABILITY AND WEATHER RESISTANCE:

The sheets are UV-resistant, resistant to chemicals and extreme temperatures

LIGHT AND HANDY:

Compared to heavy metal plates, the low weight of the PE board makes handling much easier.

Comparison with traditional solutions

COMPARED TO METAL PLATES:

NO RUST:

The PE panels do not rust and do not require any complex post-treatment.

NO RISK OF THEFT:

Since there is no scrap value, the risk of theft is eliminated.

COST SAVINGS:

Due to lower material & Maintenance costs are more economically attractive.

COMPARED TO DIRECT LABELING ON SUBSTRATES:

SUBSTRATE PROTECTION:

The panels protect the container from damage, extending its service life.

EFFICIENT RELABELING:

A clean surface and optimal conditions, e.g., through pre-labeling indoors, save time and effort when reapplying labels, making the use of spray adhesive obsolete.

OLD SOLUTIONS

LABEL +

CLEANER +

SPRAY ADHESIVE +

AUXILIARY MATERIALS +

TIME

___________________

UNCERTAINTY

Sustainability and recycling process

Our PE boards are 100% recyclable and can be reused in a closed recycling loop at the end of their service life. This reduces material consumption and protects the environment.

Occupational safety

Our solution eliminates the risks of sharp blades, aggressive cleaning agents and hazardous spray adhesives, as well as the resulting fumes. The splinter-free PE plates enable chemical-free handling and residue-free label removal without dangerous tools. In addition, labels can be conveniently applied indoors in advance, minimizing the need to work under the influence of the weather or at unsafe heights. This protects both the environment and the health of your employees.

Application and flexibility

The PE plates are available in various sizes and thicknesses and are suitable for different transport carriers such as tank containers, sea containers, tank wagons and trucks. They are used for warehouse labeling or on construction sites. Their versatility makes them the ideal solution. Two standard sizes guarantee the use of 90% of the standard holders available on the market.

Our solution in comparison

| CRITERION | PE-BOARD (BOXLAB Services) |

METAL PLATES | DIRECT LABELING |

|---|---|---|---|

| PRICE | Moderate purchase price, but cost-efficient due to deposit system | High purchase price, no deposit option | Low material cost, but high maintenance effort |

| SAFETY | No sharp edges, rounded, splinter-free | Sharp edges possible, risk of injury | Risk of adhesive residues, potentially unsafe |

| THEFT RISK | Low, no scrap value | High, can be sold as metal | No theft risk |

| SUSTAINABILITY | 100% recyclable, reusable, deposit system planned | Limited recyclability, often discarded or stolen | Surfaces often chemically cleaned and sometimes repainted/coated |

| CLEANING & MAINTENANCE | No chemical cleaning required | Time-consuming cleaning due to adhesive residues | Regular cleaning required |

| USAGE DURATION | Long-lasting, temperature and weather-resistant | Rusts in moisture, limited durability | High wear due to environmental factors |

| ASSEMBLY EFFORT | Multiple assembly options (holders, rivets, etc.) | Time-consuming assembly, often requires special holders | Direct, but difficult label removal |

| PROCESS COSTS | Low due to fast handling | High due to extensive maintenance | High due to repeated relabeling |

| COMPLIANCE WITH STANDARDS | BS 5609 certified, seawater resistant | Standards may vary by manufacturer | Difficult to comply with standards consistently |

| AVAILABILITY | Quickly available in large quantities and various formats | Depends on the supplier | Always available, no stock management required |

| ENVIRONMENTAL IMPACT | Positive due to recycling and reduced material consumption | Negative due to high material use | |

| FLEXIBILITY | Customizable for different applications | Not very flexible, specific sizes required | No customization possible, fixed size |

| NOISE POLLUTION | Quiet, no disturbing noises | Frequent rattling in holders | No noise pollution from direct labeling |

| REUSABLE OPTION | Reusable with one-time cost for the board | Reusability possible, but maintenance is high | Not reusable after label removal |

| APPLICATION | Location-independent labeling under optimal conditions | Location-independent labeling under optimal conditions | On-site labeling under all weather conditions |

Practical reports and market feedback

Our PE panels have been extensively tested in practice and successfully used in real hazardous goods transportation environments.

transportation environments. Two particularly meaningful application reports prove the reliability

and efficiency of our solution:

PRACTICAL TEST AT BASF

(TANK CARS)

BASF equipped several hundred tank cars with our PE sheets and BOXLAB labels. The tests covered various transport conditions, including national and cross-border transport. The decisive factors were the ease of label removal and the residue-free reuse of the sheets. The feedback was consistently positive:

- Process reliability: The PE sheets could be relabeled efficiently,

without additional cleaning effort. - Time savings: Employees were able to save considerable time thanks to the quick label removal.

- Cost reduction: The reusability of the sheets contributed to a significant reduction in material and disposal costs.

PRACTICAL TEST AT GRUBER FORWARDING COMPANY

(TANK CONTAINER)

Gruber Forwarding Company tested our PE panels in shuttle traffic for the transport of hazardous goods using tank containers. These tests were conducted in both national and international traffic, with regular official inspections being conducted. The Rhineland-Palatinate Ministry of Transport was present during the evaluation of the test results, examined the solution, and rated it as positive.

- Legal Compliance: The PE panels were accepted without any problems in all inspection situations, even in different countries with sometimes different legal regulations and interpretations.

- Robustness: Even with frequent reloading and adverse weather conditions, the panels remained stable and functional.

- Confidence in the Application: The drivers and logistics staff commented positively on the ease of use and robustness of the solution.

„The PE boards from BOXLAB Services have clearly proven themselves in our daily operations.

Anyone can now remove old labels in no time without any adhesive residue and immediately apply new ones – no waiting time, cleaning steps, or intermediate processes needed.

This saves time, reduces process costs, and makes our workflows significantly more efficient. BASF continues to rely on this solution – more than 2,500 boards are already in use, and the number keeps growing.“

Dominic Volz

Head of Technical Office – Railcars, Locomotive and Tank Workshops, BASF

„Labels literally burn into tank containers and metal plates during frequent commuter traffic – sun and weather further intensify this effect. Our employees have to remove these residues manually, which requires considerable effort. On the BOXLAB PE plates, however, labels can be removed residue-free and in seconds. For containers suitable for this solution, we can save significant time and money. The plates have also proven themselves reliable in practical tests in cross-border traffic and during inspections.“

Werner Weber

Managing Director, Gruber GmbH & Co. KG

Our PE plates are already successfully established on the market and are increasingly being used by companies in the hazardous goods transportation sector. The positive feedback from the field has confirmed that the combination of PE plates and BOXLAB labels is an innovative, practical and economical solution.

Holistic process:

The extensive tests and the consistently positive feedback from the field prove that our PET panels not only meet the requirements for modern and sustainable hazardous goods labeling in theory, but also in practice. They offer a legally compliant, sustainable and cost-effective alternative to conventional labeling methods and have already proven themselves in various industrial applications.

Application:

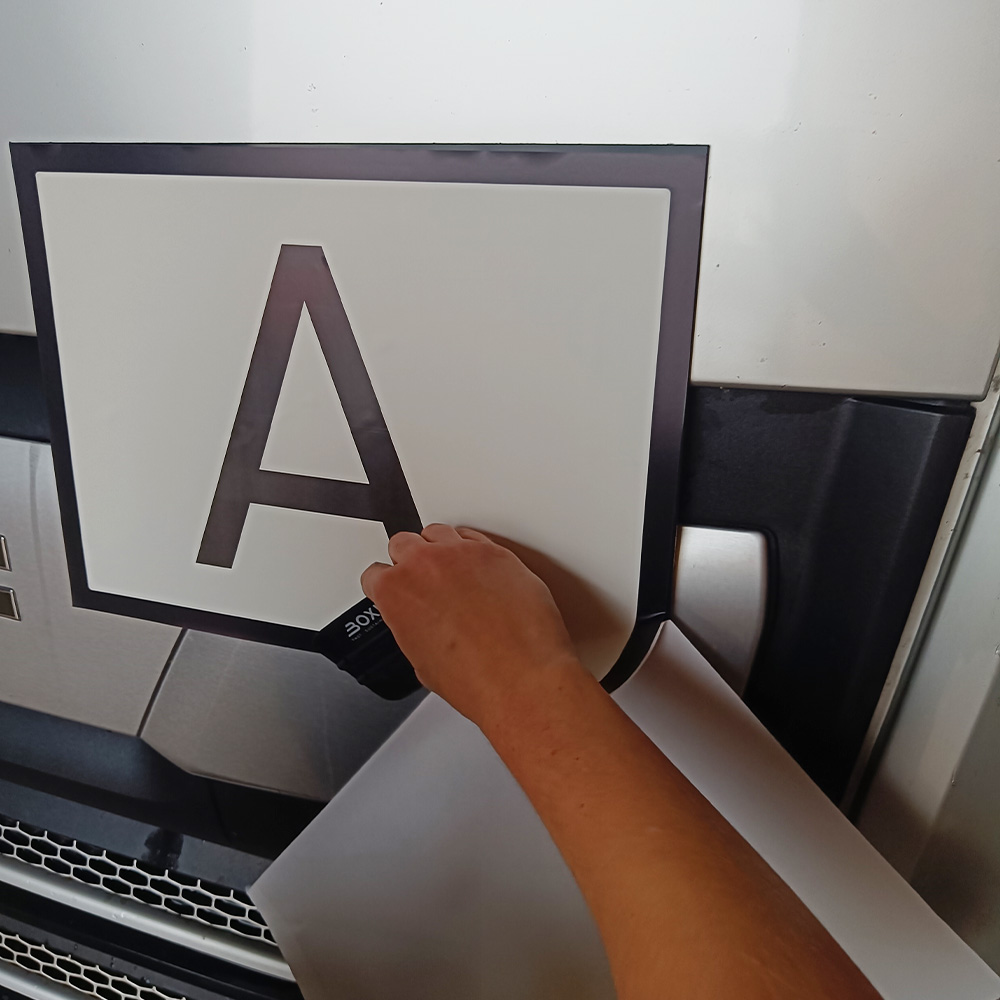

The label is applied cleanly and bubble-free to the PE board using a squeegee, ensuring secure and professional adhesion. If necessary, the label can be easily removed without leaving any residue. If necessary, a safety scraper can be used to create an initial attack surface without damaging the surface of the panel.

Conclusion

The innovative combination of PE plates and BOXLAB labels offers a comprehensive solution for the challenges of hazardous goods labeling. Our solution combines legal compliance, sustainability and cost-effectiveness in a tried-and-tested system.

The successful market establishment of our PE plates shows that our solution meets the high requirements of the industry. Our solution stands for sustainable, 100% safe and cost-efficient labeling in the global transport of dangerous goods.

At BOXLAB Services, we not only offer certified hazardous goods labels and PE plates, but also the expertise that makes the difference. Our products are specially developed for the toughest applications – from extreme temperatures and aggressive chemicals to demanding transportation conditions.

Further accessories for your success

Our range includes sophisticated solutions that increase your efficiency and simplify work processes.

Our PE sheets offer a robust and residue-free surface for secure labeling. The BOXLAB machine cleaning cloth, in combination with the BOXLAB BIO cleaner, ensures thorough cleaning for optimum label adhesion. For professional applications, we also offer spray adhesive for reliable attachment.

Our training materials support trainers and professionals with practical solutions, including training sets with hazardous goods labels and magnetic placards.

PE plates

Our PE plates are high-quality products that serve as an optimal base for labels. Thanks to their robust properties and easy labeling without the need for additional cleaning, they offer an efficient solution for various applications. The PE plates are lightweight, easy to handle and can be used both indoors and outdoors. Their robust construction makes them a reliable support in your labeling process.

Auxiliary materials

Our aids are not just simple tools, but indispensable companions for your labeling processes. From injury-free safety scrapers to environmentally friendly BIO cleaners and the practical BOXLAB squeegee – each of our tools has been developed to make your day-to-day work easier and ensure legally compliant results. Quality and functionality are at the heart of our products.

Training sets

Our training sets offer a practical introduction to the world of dangerous goods labeling and packaging. They contain high-quality samples of hazardous goods labels as well as additional accessories such as safety scrapers and BIO cleaners. These kits are ideal for training and education to provide professionals with a comprehensive overview of legal requirements and best practice.

Spray adhesive

Our spray adhesive is the ideal solution for demanding conditions. Whether in rain, snow or difficult surfaces – it ensures reliable adhesion of your labels. Even labels that have already been removed can be easily reattached without compromising security. Developed for professional use, our spray adhesive provides a strong and durable bond. Discover the optimum support for your labeling – even under the toughest conditions!

BOXLAB machine cleaning cloth

With a high-quality cotton-polyester blend, ideal for machine cleaning, surface care and cleaning containers – in perfect combination with the BOXLAB BIO cleaner for optimum results. The BOXLAB machine cleaning cloth (approx. 400 x 400 mm) made from a hard-wearing cotton-polyester blend offers outstanding durability and absorbency for demanding cleaning tasks. Thanks to its generous ~ 40 x 40 cm surface area, it is perfect for cleaning machines, surfaces and containers. The double warp prevents fraying and guarantees a long service life. In combination with the BOXLAB BIO cleaner, you can achieve thorough and effective cleaning that ensures the adhesion of hazardous goods labels. Ideal for professional use – in garages, logistics and when preparing labels.

Das Bild zeigt den BOXLAB BIO-Reiniger zusammen mit einem BOXLAB Maschinenputztuch im Motorraum eines Fahrzeugs. Das Tuch liegt auf einer verschmutzten Oberfläche und verdeutlicht die effektive Reinigung von öligen und schmutzigen Bereichen. Durch die Kombination aus hochwertigem Maschinenputztuch und dem BOXLAB BIO-Reiniger lassen sich Motorraum und andere schwierige Oberflächen schnell und gründlich säubern, um eine ideale Grundlage für Etikettierungen oder weitere Reinigungsprozesse zu schaffen.

We are always there for you personally.

When it comes to dangerous goods, there is no room for compromise. Rely on quality, practical solutions and expert knowledge – for maximum safety and 100% compliance.