Stubborn residues and loss of time

Anyone who works with hazardous goods labels knows the frustration: once applied, many labels are almost impossible to remove. This results in scraped-off residue, damaged container surfaces, and an enormous amount of time wasted. Labels that have baked on and stuck for months often adhere permanently to metal surfaces such as containers and drums. Previous solutions are laborious, unreliable, or damage the surfaces. In an industry where speed, cleanliness, and safety are crucial, an efficient solution was long overdue.

The new BOXLAB label remover from Technolit

BOXLAB Services has taken on this challenge and, in an exclusive cooperation with Technolit, has developed an innovative label remover that sets new standards. The spray works where other products give up: it removes even the most stubborn labels quickly and without damaging the material. It was specially designed for strongly adhering dangerous goods labels on metal surfaces such as containers, drums, and other transport containers. The revolutionary effect of the spray has even impressed professionals in practice.

More than just a label remover

The BOXLAB label remover from Technolit is more than just a simple cleaning product. It is a key element that optimizes your work processes and increases efficiency.

Saves time and reduces rework:

The spray removes labels quickly and reliably. This ensures clean, residue-free surfaces that are ready for new, standard-compliant labeling without time-consuming rework.

The perfect addition to the portfolio:

The label remover completes the BOXLAB portfolio. It is the ideal alternative when PE panels cannot be used and offers the same efficiency.

Unbeatable versatility:

It also removes labels that have been exposed to wind and weather for a long time and even works on labels treated with spray adhesive.

Simple hazard communication:

The product labeling is particularly clear thanks to only two GHS pictograms (flame & exclamation mark).

APPLICATION AND SAFETY INSTRUCTIONS

The application is very simple, but safety-relevant.

Application:

- Shake can well before use.

- Spray the label from a distance of about 20 cm.

- Allow to act for a short time.

- Then lift the label off with a spatula.

Tip: Protect sensitive surfaces (e.g., painted containers) with masking tape beforehand to avoid possible color detachment.

Try it now and order immediately

Ready for a revolution in your work processes? Test the efficiency of our label remover yourself and experience how effortlessly you can remove stubborn labels and adhesive residues. Order the product directly from our shop and ensure clean, professional surfaces.

Frequently asked questions (FAQ)

What is the BOXLAB label remover?

The BOXLAB Label Remover is a powerful aerosol spray that has been specially developed to quickly and gently remove even the most stubborn and baked-on labels and adhesive residues from metal surfaces such as containers and barrels.

How do I use the product?

Simply spray onto the affected area, leave to take effect for a short time, and then remove the label with a scraper or similar tool.

Kann ich das Produkt auch auf lackierten Oberflächen verwenden?

Yes, you can also use it on painted surfaces. However, to avoid possible damage, we recommend protecting sensitive areas with masking tape beforehand.

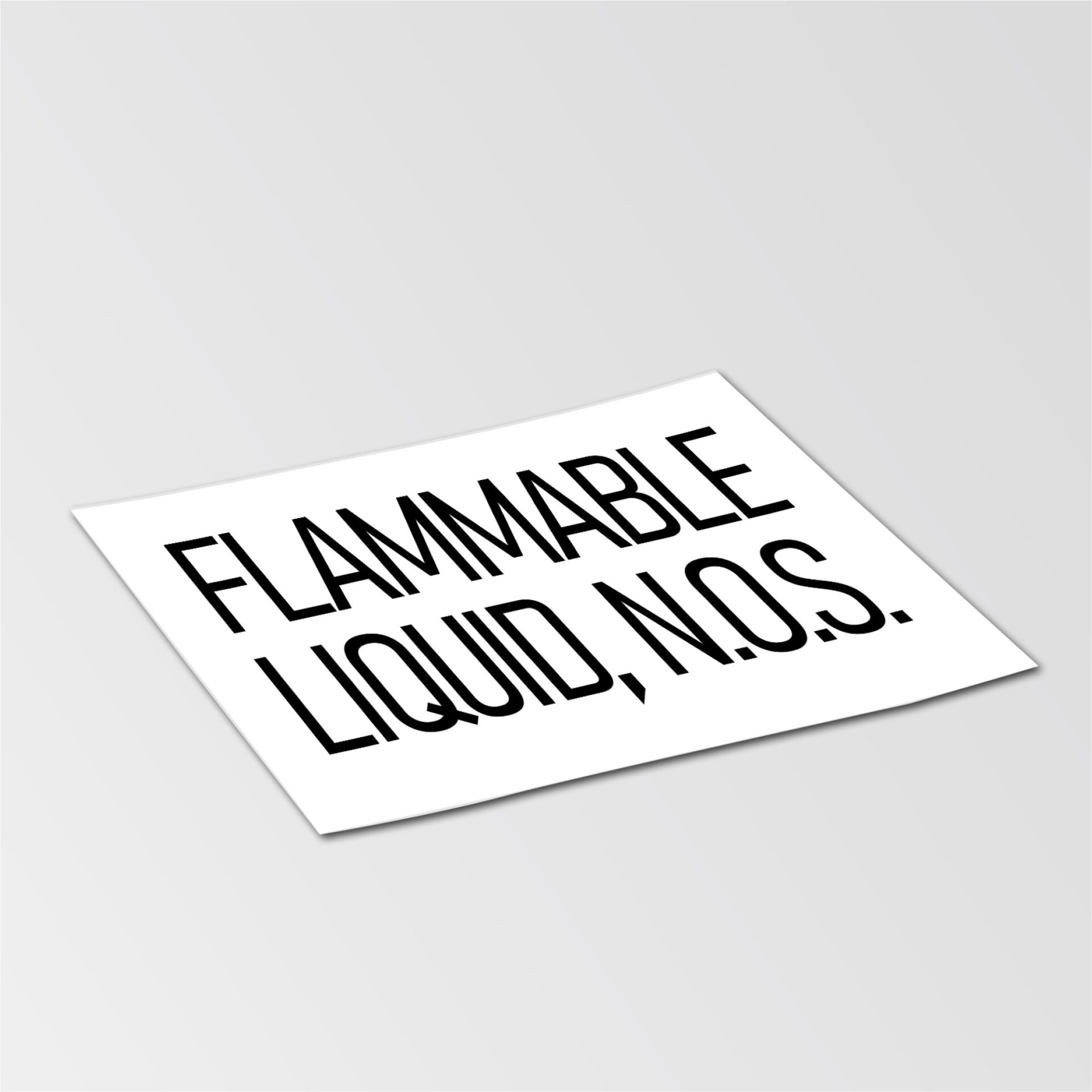

Is the spray dangerous?

Yes, the product is an extremely flammable aerosol and is pressurized. We strongly recommend that you follow the safety instructions on the packaging and in the safety data sheet (SDS).

Wo kann ich den Etikettenlöser kaufen?

The product is available exclusively from BOXLAB Services.

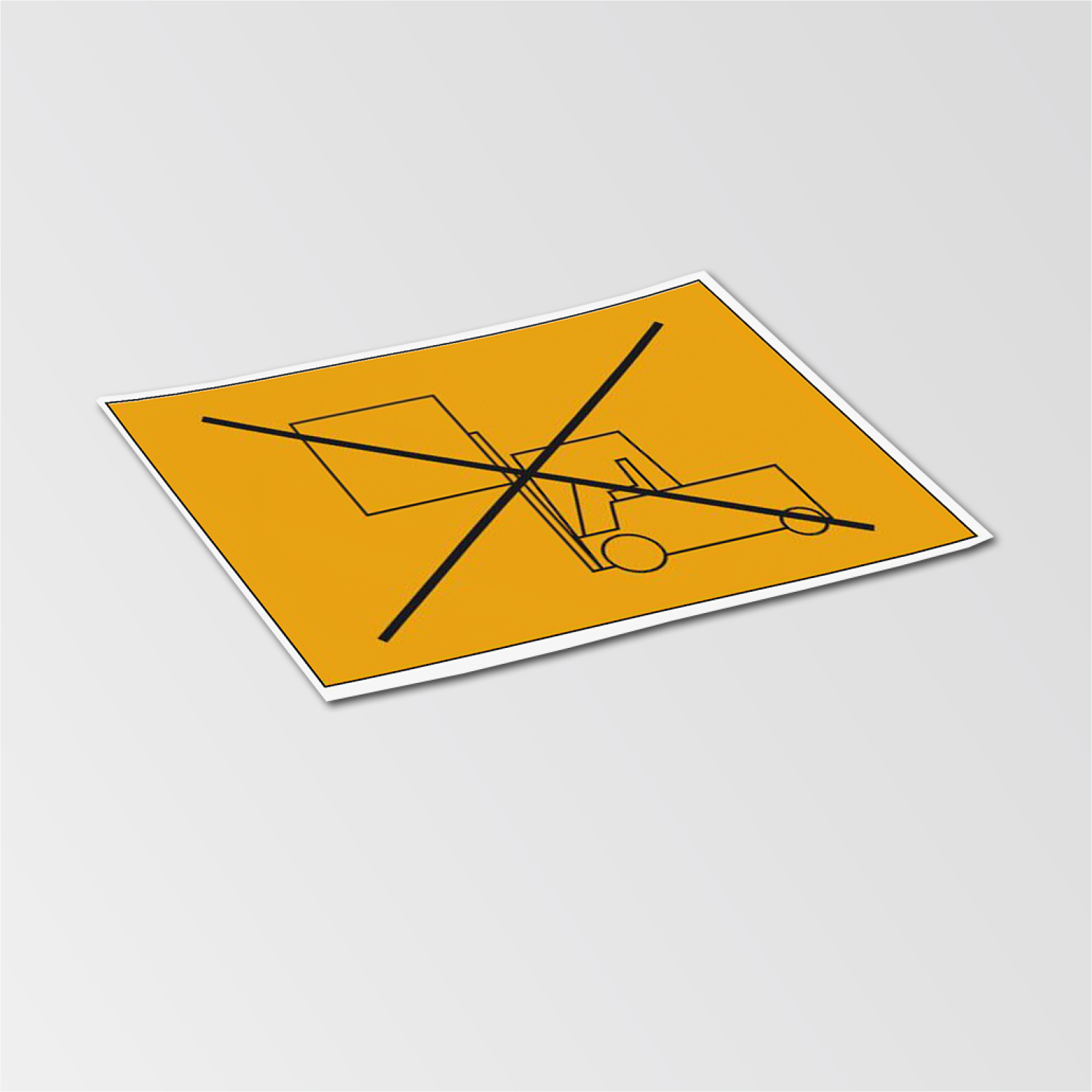

- Danger: Extremely flammable aerosol, container is under pressure.

- Recommended PPE: When using, wear safety glasses, protective gloves, and closed clothing.

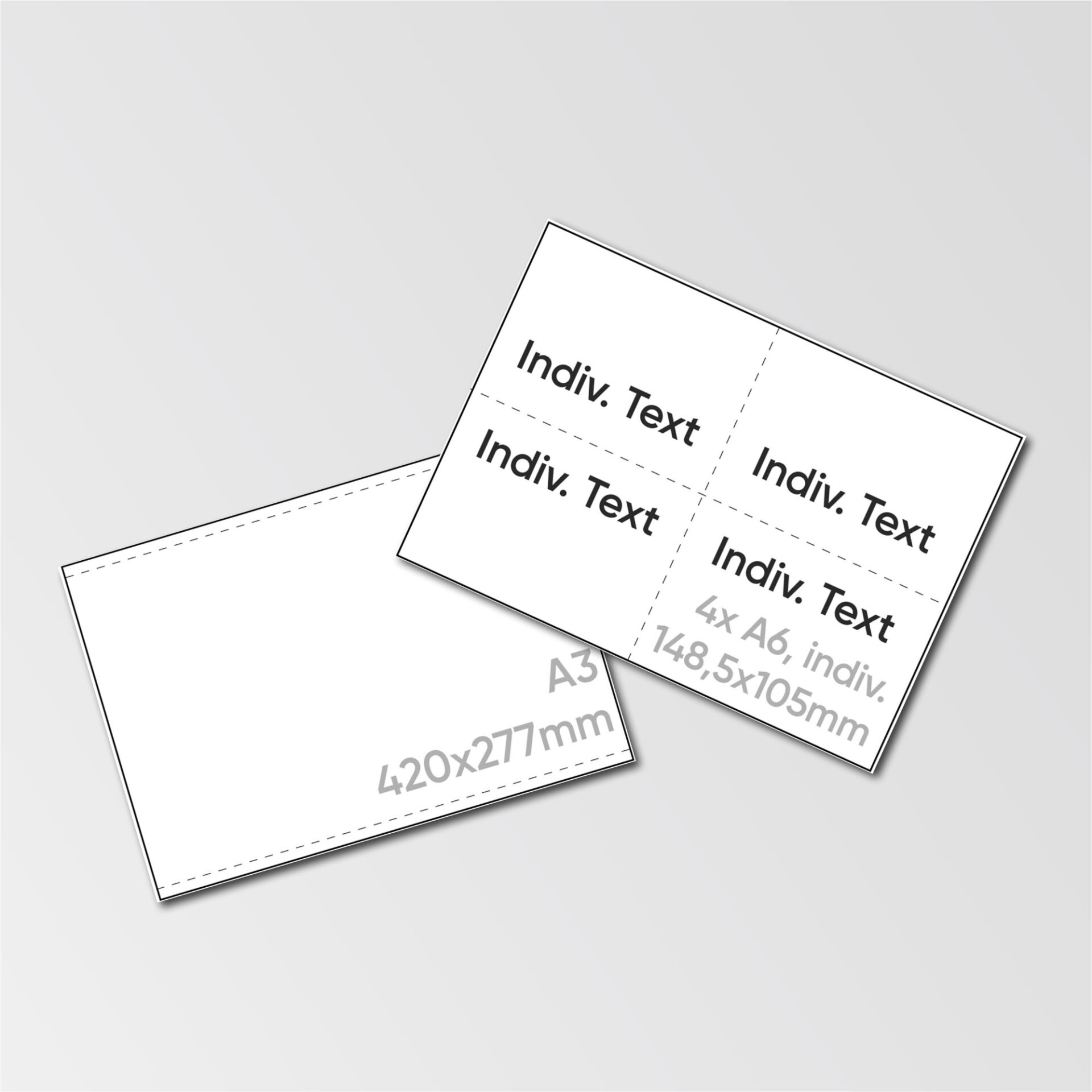

- The product has the UN 1950 AEROSOLS marking and can be transported as a Limited Quantity (LQ) up to 1 liter.

- The safety data sheet (SDS) is available as a PDF – Download

The missing piece of the puzzle is here

With the BOXLAB label remover, BOXLAB Services once again presents a practical innovation for the hazardous goods industry. We have found the perfect symbiosis of adhesion and removability and now offer a continuous process chain – from application to effortless removal. If you value efficiency, safety, and clean processes, this solution is a must. The BOXLAB Label Remover is now available exclusively from BOXLAB Services.